ASTM F436 Specification

ASTM F436 is a standard material and dimensional specification for hardened steel washers, intended for general-purpose mechanical and structural use with bolts, nuts, studs, and other internally and externally threaded fasteners. This specification covers chemical, mechanical and dimensional requirements for both type 1 & type 3 hardened steel washers for use with fasteners having nominal thread diameters of 1/4 through 4 inch. Boltport manufactures and stocks full range of type 1 & type 3 steel washers to ASTM F436 specification.

Grade Type

| Grade | Steel Description | Identification Marking |

|---|---|---|

| Type 1 | Hardened Steel | "F436" |

| Type 3 | Weathering Steel | "F436 3" |

Chemical Composition [Note A]

| Elements | Composition, % | ||

|---|---|---|---|

| Type 1 | Type 3 [Note B] | ||

| Phosphorus, max | Heat | 0.040 | 0.040 |

| Product | 0.050 | 0.045 | |

| Sulfur, max | Heat | 0.050 | 0.050 |

| Product | 0.060 | 0.055 | |

| Silicon | Heat | -- | 0.15 - 0.35 |

| Product | -- | 0.13 - 0.37 | |

| Chromium | Heat | -- | 0.45 - 0.65 |

| Product | -- | 0.42 - 0.68 | |

| Nickel | Heat | -- | 0.25 - 0.45 |

| Product | -- | 0.22 - 0.48 | |

| Copper | Heat | -- | 0.25 - 0.45 |

| Product | -- | 0.22 - 0.48 | |

Mechanical Properties [Hardness Requirement]

| Surface | Through Hardened | Carburized | Carburized and Hardened |

|---|---|---|---|

| Plain | 38 - 45 HRC | 69 - 73 HRA | 30 HRC or 65 HRA |

| Hot Dip Galvanized | 26 - 45 HRC | 79 - 83 HR15N |

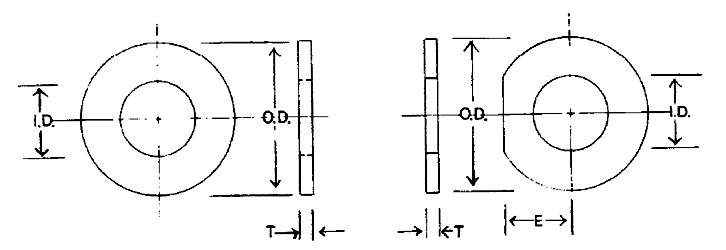

Dimensions [Hardened Circular, Clipped Circular, and Extra-Thick Washers]

| Circular, Clipped Circular and Extra Thick | Thickness(T), in. | Clipped | |||||

|---|---|---|---|---|---|---|---|

| Nominal Size |

Nominal Outside Diameter (OD), in. |

Nominal Inside Diameter (ID), in. |

Circular and Clipped | Extra Thick | Min. Edge Distance(E)A, in. |

||

| min | max | min | max | ||||

| 1/4 | 0.625 | 0.281 | 0.051 | 0.080 | - | - | 0.219 |

| 5/16 | 0.688 | 0.344 | 0.051 | 0.080 | - | - | 0.281 |

| 3/8 | 0.813 | 0.406 | 0.051 | 0.080 | - | - | 0.344 |

| 7/16 | 0.922 | 0.469 | 0.051 | 0.080 | - | - | 0.406 |

| 1/2 | 1.063 | 0.531 | 0.097 | 0.177 | 0.305 | 0.375 | 0.438 |

| 9/16 | 1.188 | 0.625 | 0.110 | 0.177 | 0.305 | 0.375 | 0.500 |

| 5/8 | 1.313 | 0.688 | 0.122 | 0.177 | 0.305 | 0.375 | 0.563 |

| 3/4 | 1.468 | 0.813 | 0.122 | 0.177 | 0.305 | 0.375 | 0.656 |

| 7/8 | 1.750 | 0.938 | 0.136 | 0.177 | 0.305 | 0.375 | 0.781 |

| 1 | 2.000 | 1.063 | 0.136 | 0.177 | 0.305 | 0.375 | 0.875 |

| 1 1/8 | 2.250 | 1.188 | 0.136 | 0.177 | 0.305 | 0.375 | 1.000 |

| 1¼ | 2.500 | 1.375 | 0.136 | 0.177 | 0.305 | 0.375 | 1.094 |

| 1 3/8 | 2.750 | 1.500 | 0.136 | 0.177 | 0.305 | 0.375 | 1.219 |

| 1 ½ | 3.000 | 1.625 | 0.136 | 0.177 | 0.305 | 0.375 | 1.313 |

| 1 ¾ | 3.375 | 1.875 | 0.178B | 0.28B | 0.305 | 0.375 | 1.531 |

| 2 | 3.750 | 2.125 | 0.178B | 0.28B | 0.305 | 0.375 | 1.750 |

| 2 ¼ | 4.000 | 2.375 | 0.24C | 0.34C | 0.305 | 0.375 | 2.000 |

| 2 ½ | 4.500 | 2.625 | 0.24C | 0.34C | 0.313 | 0.375 | 2.188 |

| 2 ¾ | 5.000 | 2.875 | 0.24C | 0.34C | 0.313 | 0.375 | 2.406 |

| 3 | 5.500 | 3.125 | 0.24C | 0.34C | 0.313 | 0.375 | 2.625 |

| 3 ¼ | 6.000 | 3.375 | 0.24C | 0.34C | 0.313 | 0.375 | 2.875 |

| 3 ½ | 6.500 | 3.625 | 0.24C | 0.34C | 0.313 | 0.375 | 3.063 |

| 3 ¾ | 7.000 | 3.875 | 0.24C | 0.34C | 0.313 | 0.375 | 3.313 |

| 4 | 7.500 | 4.125 | 0.24C | 0.34C | 0.313 | 0.375 | 3.500 |

Note :

A : Clipped edge E shall be not closer than 7/8 of the bolt diameter from the center of the washer.

B : 3/16 in. nominal.

C : 1/4 in. nominal.

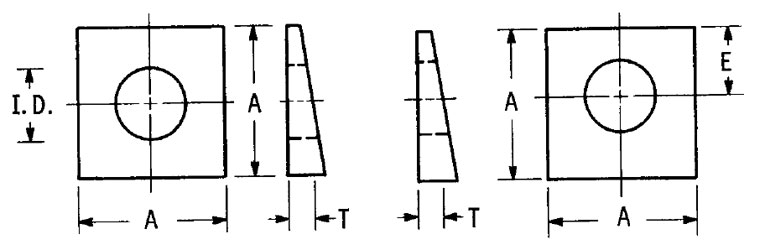

Dimensions [Hardened Bevelled Washers]

| Bolt Size, in. | Min Side Dimension (A), in. |

Nominal Inside Diameter(I.D), in. |

Mean Thickness (T), in. |

Slope or Taper in Thickness |

Nominal Edge Distance(E)B, in. |

|---|---|---|---|---|---|

| 1/2 | 1 3/4 | 17/32 | 5/16 | 1.6 | 7/16 |

| 5/8 | 1 3/4 | 11/16 | 5/16 | 1.6 | 9/16 |

| 3/4 | 1 3/4 | 13/16 | 5/16 | 1.6 | 21/32 |

| 7/8 | 1 3/4 | 15/16 | 5/16 | 1.6 | 25/32 |

| 1 | 1 3/4 | 1 1/8 | 5/16 | 1.6 | 7/8 |

| 1 1/8 | 2 1/4 | 1 1/4 | 5/16 | 1.6 | 1 |

| 1 1/4 | 2 1/4 | 1 3/8 | 5/16 | 1.6 | 1 3/32 |

| 1 3/8 | 2 1/4 | 1 1/2 | 5/16 | 1.6 | 1 7/32 |

| 1 1/2 | 2 1/4 | 1 5/8 | 5/16 | 1.6 | 1 5/16 |

Note :

A : Rectangular beveled washers shall conform to the dimensions shown above, except that one side may be longer than that shown for the A dimension.

B : Clipped edge E shall not be closer than 7/8 of the bolt diameter from the center of the washer.

Dimensional Tolerances

| Dimensional Characteristics | <1 in. Nominal Size |

1 through 1½ in. Nominal Size | >1 ½ through 3 in. Nominal Size |

>3in. Nominal Size |

|---|---|---|---|---|

| Nominal diameter of hole, in. | -0, +0.032 | -0, +0.063 | -0, +0.063 | -0, +0.125 |

| Nominal outside diameter, in. | +_0.032 | +_0.063 | +_ 0.063 | +_ 0.125 |

| Flatness: max deviation from straightedge placed on cut side shall not exceed (in.) | 0.010 | 0.015 | 0.020 | 0.032 |

| Concentricity, in : center of hole to outside diameter | 0.030 FIRA | 0.060 FIRA | 0.090 FIRA | 0.250 FIRA |

| Burr shall not project above immediately adjacent washer surface more than (in.) | 0.010 | 0.015 | 0.020 | 0.025 |

A : Full indicator runout.