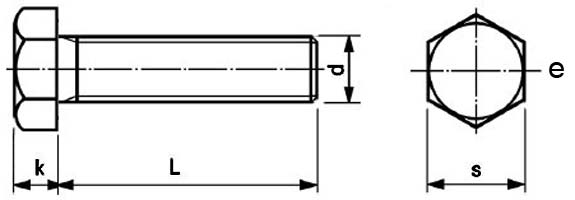

IS 1363-2 Hexagon Head Screws

Dimensions of IS 1363-2 Preferred Threads

| Thread (d) | pa | a | c max | da max | dw min | e min | k | kwb min | r min | s | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| max | min | nom | max | min | nom = max | min | ||||||||

| M5 | 0.8 | 2.4 | 0.8 | 0.5 | 6 | 6.74 | 8.63 | 3.5 | 3.875 | 3.125 | 2.19 | 0.2 | 8.00 | 7.64 |

| M6 | 1 | 3 | 1 | 0.5 | 7.2 | 8.74 | 10.89 | 4 | 4.375 | 3.625 | 2.54 | 0.25 | 10.00 | 9.64 |

| M8 | 1.25 | 4.00 | 1.25 | 0.6 | 10.2 | 11.47 | 14.20 | 5.3 | 5.675 | 4.925 | 3.45 | 0.4 | 13.00 | 12.57 |

| M10 | 1.5 | 4.5 | 1.5 | 0.6 | 12.2 | 14.47 | 17.59 | 6.4 | 6.85 | 5.95 | 4.17 | 0.4 | 16.00 | 15.57 |

| M12 | 1.75 | 5.30 | 1.75 | 0.6 | 14.7 | 16.47 | 19.85 | 7.5 | 7.95 | 7.05 | 4.94 | 0.6 | 18.00 | 17.57 |

| M16 | 2 | 6 | 2 | 0.8 | 18.7 | 22 | 26.17 | 10 | 10.75 | 9.25 | 6.48 | 0.6 | 24.00 | 23.16 |

| M20 | 2.5 | 7.5 | 2.5 | 0.8 | 24.4 | 27.7 | 32.95 | 12.5 | 13.40 | 11.6 | 8.12 | 0.8 | 30.00 | 29.16 |

| M24 | 3 | 9 | 3 | 0.8 | 28.4 | 33.25 | 39.55 | 15 | 15.9 | 14.1 | 9.87 | 0.8 | 36 | 35 |

| M30 | 3.5 | 10.5 | 3.5 | 0.8 | 35.4 | 42.75 | 50.85 | 18.7 | 19.75 | 17.65 | 12.36 | 1 | 46 | 45 |

| M36 | 4 | 12 | 4 | 0.8 | 42.4 | 51.11 | 60.79 | 22.5 | 23.55 | 21.45 | 15.02 | 1 | 55.0 | 53.8 |

| M42 | 4.5 | 13.5 | 4.5 | 1 | 48.6 | 59.65 | 71.3 | 26 | 27.05 | 24.95 | 17.47 | 1.2 | 65.0 | 63.1 |

| M48 | 5 | 15 | 5 | 1 | 56.6 | 69.45 | 82.6 | 30 | 31.05 | 28.95 | 20.27 | 1.6 | 75.0 | 73.1 |

| M56 | 5.5 | 16.5 | 5.5 | 1 | 67 | 78.66 | 93.56 | 35 | 36.25 | 33.75 | 23.63 | 2 | 85.0 | 82.8 |

| M64 | 6 | 18 | 6 | 1 | 75 | 88.16 | 104.86 | 40 | 41.25 | 38.75 | 27.13 | 2 | 95.0 | 92.8 |

Dimensions of IS 1363-2 Non-Preferred Threads

| Thread (d) | pa | a | c max | da max | dw min | e min | k | kwb min | r min | s | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| max | min | nom | max | min | nom = max | min | ||||||||

| M14 | 2 | 6 | 2 | 0.6 | 16.7 | 19.15 | 22.78 | 8.8 | 9.25 | 8.35 | 5.85 | 0.6 | 21.00 | 20.16 |

| M18 | 2.5 | 7.5 | 2.5 | 0.8 | 21.2 | 24.85 | 29.56 | 11.5 | 12.4 | 10.6 | 7.42 | 0.6 | 27.00 | 26.16 |

| M22 | 2.5 | 7.5 | 2.5 | 0.8 | 26.4 | 31.35 | 37.29 | 14 | 14.9 | 13.1 | 9.17 | 0.8 | 34 | 33 |

| M27 | 3 | 9 | 3 | 0.8 | 32.4 | 38 | 45.2 | 17 | 17.9 | 16.1 | 11.27 | 1 | 41 | 40 |

| M33 | 3.5 | 10.5 | 3.5 | 0.8 | 38.4 | 46.55 | 55.37 | 21 | 22.05 | 19.95 | 13.97 | 1 | 50 | 49 |

| M39 | 4 | 12 | 4 | 1 | 45.4 | 55.86 | 66.44 | 25 | 26.05 | 23.95 | 16.77 | 1 | 60 | 58.8 |

| M45 | 4.5 | 13.5 | 4.5 | 1 | 52.6 | 64.7 | 76.95 | 28 | 29.05 | 26.95 | 18.87 | 1.2 | 70 | 68.1 |

| M52 | 5 | 15 | 5 | 1 | 62.6 | 74.2 | 88.25 | 33 | 34.25 | 31.75 | 22.23 | 1.6 | 80 | 78.1 |

| M60 | 5.5 | 16.5 | 5.5 | 1 | 71 | 83.41 | 99.21 | 38 | 39.25 | 36.75 | 25.73 | 2 | 90 | 87.8 |

Specifications and reference standards

| Material | Steel | |

|---|---|---|

| General Requirements | International Standard | ISO 8992 |

| Thread | Tolerance | 8g |

| International Standards | ISO 724, ISO 965-1 | |

| Mechanical Properties | Property Classa | d≤ 39mm: 3.6, 4.6, 4.8 d > 39mm: as agreed |

| International Standard | d≤ 39mm: 3.6, 4.6, 4.8 d > 39mm: as agreed |

|

| Tolerances | Product grade | C |

| International Standard | ISO 4759-1 | |

| Finish and/or coating | As Processed Requirements for electroplating are converted in ISO 4042. Requirements for non-electrolytically applied zinc flake coatings are converted in ISO 10683 If different electroplating requirements are desired or if requirements are needed for other finishes, they should be agreed between custom and supplier. |

|

| Acceptability | For acceptance procedure, see ISO 3269 | |

| a For other property classes see ISO 898-1 | ||