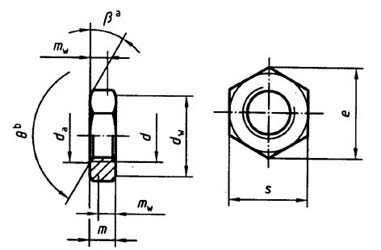

IS 1364-4 Hexagon Thin Nuts, Chamfered

β = 15° to 30°

ø = 110° to 120°

Dimensions of IS 1364-4 Hexagon Thin Nuts, Chamfered - Preferred Threads

| Thread (d) | M 1.6 | M 2 | M 2.5 | M 3 | M 4 | M 5 | M 6 | M 8 | M 10 | M 12 | |

| pa | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | |

| da | max | 1.84 | 2.3 | 2.9 | 3.45 | 4.6 | 5.75 | 6.75 | 8.75 | 10.8 | 13 |

| min | 1.60 | 2.0 | 2.5 | 3.00 | 4.0 | 5.00 | 6.00 | 8.00 | 10.0 | 12 | |

| dw min | 2.4 | 3.1 | 4.1 | 4.60 | 5.9 | 6.90 | 8.9 | 11.6 | 14.6 | 16.6 | |

| e min | 3.41 | 4.32 | 5.45 | 6.01 | 7.66 | 8.79 | 11.05 | 14.38 | 17.77 | 20.03 | |

| m | max | 1.00 | 1.20 | 1.60 | 1.80 | 2.20 | 2.70 | 3.2 | 4.0 | 5.0 | 6.0 |

| min | 0.75 | 0.95 | 1.35 | 1.55 | 1.95 | 2.45 | 2.9 | 3.7 | 4.7 | 5.7 | |

| mw min | 0.6 | 0.8 | 1.1 | 1.2 | 1.6 | 2 | 2.3 | 3 | 3.8 | 4.6 | |

| s | nom = max | 3.20 | 4.00 | 5.00 | 5.50 | 7.00 | 8.00 | 10.00 | 13.00 | 16.00 | 18.00 |

| min | 3.02 | 3.82 | 4.82 | 5.32 | 6.78 | 7.78 | 9.78 | 12.73 | 15.73 | 17.73 | |

| Thread (d) | M 16 | M 20 | M 24 | M 30 | M 36 | M 42 | M 48 | M 56 | M 64 | |

| pa | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | |

| da | max | 17.3 | 21.6 | 25.9 | 32.4 | 38.9 | 45.4 | 51.8 | 60.5 | 69.1 |

| min | 16.0 | 20.0 | 24.0 | 30.0 | 36.0 | 42.0 | 48.0 | 56.0 | 64.0 | |

| dw min | 22.5 | 27.7 | 33.3 | 42.8 | 51.1 | 60 | 69.5 | 78.7 | 88.2 | |

| e min | 26.75 | 32.95 | 39.55 | 50.85 | 60.79 | 71.3 | 82.6 | 93.56 | 104.86 | |

| m | max | 8.00 | 10.0 | 12.0 | 15.0 | 18.0 | 21.0 | 24.0 | 28.0 | 32.0 |

| min | 7.42 | 9.1 | 10.9 | 13.9 | 16.9 | 19.7 | 22.7 | 26.7 | 30.4 | |

| mw min | 5.9 | 7.3 | 8.7 | 11.1 | 13.5 | 15.8 | 18.2 | 21.4 | 24.3 | |

| s | nom = max | 24.00 | 30.00 | 36 | 46 | 55.0 | 65.0 | 75.0 | 85.0 | 95.0 |

| min | 23.67 | 29.16 | 35 | 45 | 53.8 | 63.1 | 73.1 | 82.8 | 92.8 | |

Dimensions of IS 1364-4 Non-Preferred Threads

| Thread (d) | M 3.5 | M 14 | M 18 | M 22 | M 27 | M 33 | M 39 | M 45 | M 52 | M 60 | |

| pa | 0.6 | 2 | 2.5 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | |

| da | max | 4.0 | 15.1 | 19.5 | 23.7 | 29.1 | 35.6 | 42.1 | 48.6 | 56.2 | 64.8 |

| min | 3.5 | 14.0 | 18.0 | 22.0 | 27.0 | 33.0 | 39.0 | 45.0 | 52.0 | 60.0 | |

| dw min | 5.1 | 19.6 | 24.9 | 31.4 | 38 | 46.6 | 55.9 | 64.7 | 74.2 | 83.4 | |

| e min | 6.58 | 23.36 | 29.56 | 37.29 | 45.2 | 55.37 | 66.44 | 76.95 | 88.25 | 99.21 | |

| m | max | 2.00 | 7.00 | 9.00 | 11.0 | 13.5 | 16.5 | 19.5 | 22.5 | 26.0 | 30.0 |

| min | 1.75 | 6.42 | 8.42 | 9.9 | 12.4 | 15.4 | 18.2 | 21.2 | 24.7 | 28.7 | |

| mw min | 1.4 | 5.1 | 6.7 | 7.9 | 9.9 | 12.3 | 14.6 | 17 | 19.8 | 23 | |

| s | nom = max | 6.00 | 21.00 | 27.00 | 34 | 41 | 50 | 60.0 | 70.0 | 80.0 | 90.0 |

| min | 5.82 | 20.67 | 26.16 | 33 | 40 | 49 | 58.8 | 68.1 | 78.1 | 87.8 | |

- p is the pitch of the thread.

Specifications and reference standards

| Material | Steel | Stainless steel | Non-ferrous metal | |

| General Requirements | International Standard | ISO 8992 | ||

| Thread | Tolerance | 6H | ||

| International Standards | ISO 724, ISO 965-1 | |||

| Mechanical Properties | Property Classa | d < M3 : as agreed M3 ≤ d ≤ M39 : 4, 5 d > M39 : as agreed |

d ≤ M24 : A2-035, A4-035 M24 < d ≤ M39 : A2-025, A4-025 |

Materials specified in ISO 8839 |

| International Standard | d < M3 : as agreed M3≤d ≤ M39 : ISO 898-2 d > M39: as agreed |

d ≤ M39 : ISO 3506-2 d > M39: as agreed |

||

| Tolerances | Product grade | d < M16 : A d > M16 : B |

||

| International Standard | ISO 4759-1 | |||

| Finish and/or coating | As Processed Requirements for electroplating are converted in ISO 4042. Requirements for non-electrolytically applied zinc If different electroplating requirements are desired or if requirements are needed for other finishes, Limits for surface discontinuities are covered in ISO 6157-2 |

Plain | Plain Requirements for electroplating are covered in ISO 4042. |

|

| Acceptability | For acceptance procedure, see ISO 3269 | |||