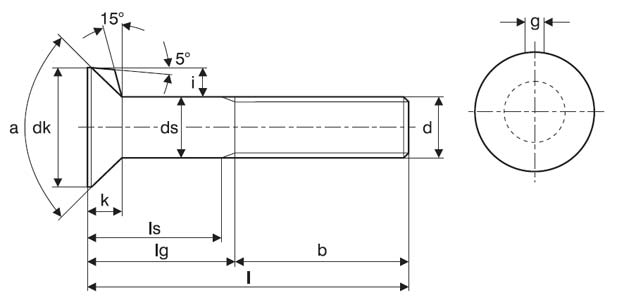

DIN 604 : Flat Countersunk Nib Bolts

Dimensions of Flat Countersunk Nib Bolts

| Nominal size and thread diameter d | Pitch of thread p | Thread Length b | Diameter of Countersunk head dk | Diameter of unthreaded shank ds' | Width of nib g | i | Depth of head k | a | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Coarse pitch | Bolt ≤ 125 | Bolt 125 - 200 | Bolt ≥ 200 | max | min | max | min | max | min | max | max | min | max | |

| M 6 | 1.0 | 18 | 24 | - | 12.55 | 11.45 | 6 | 5.52 | 2.5 | 2.10 | 2.5 | 4.0 | 90° | 95° |

| M 8 | 1.25 | 22 | 28 | 41 | 16.55 | 15.45 | 8 | 7.42 | 3.0 | 2.60 | 3.5 | 5.0 | 90° | 95° |

| M 10 | 1.5 | 26 | 32 | 45 | 19.65 | 18.35 | 10 | 9.42 | 3.2 | 2.72 | 4.2 | 5.5 | 90° | 95° |

| M 12 | 1.75 | 30 | 36 | 49 | 24.65 | 23.35 | 12 | 11.30 | 3.6 | 3.12 | 5.7 | 7.0 | 90° | 95° |

| M 16 | 2.0 | 38 | 44 | 57 | 32.80 | 31.20 | 16 | 15.30 | 4.2 | 3.72 | 7.5 | 9.0 | 90° | 95° |

| M 20 | 2.5 | 46 | 52 | 65 | 32.80 | 31.20 | 20 | 19.16 | 5.4 | 4.92 | 5.7 | 11.5 | 60° | 65° |

| M 24 | 3.0 | 54 | 60 | 73 | 38.80 | 37.20 | 24 | 23.16 | 6.6 | 6.02 | 6.7 | 13.0 | 60° | 65° |

| d | M 6 | M 8 | M 10 | M 12 | M 16 | M 20 | M 24 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Size | l min | l max | ls min | lg max | ls min | lg max | ls min | lg max | ls min | lg max | ls min | lg max | ls min | lg max | ls min | lg max |

| 20 | 18.95 | 21.05 | - | 9 | - | 11.5 | - | 13 | - | - | - | - | - | - | - | - |

| 25 | 23.95 | 26.05 | - | 9 | - | 11.5 | - | 13 | - | 16 | - | - | - | - | - | - |

| 30 | 28.95 | 31.05 | - | 9 | - | 11.5 | - | 13 | - | 16 | - | 19 | - | - | - | - |

| 35 | 33.75 | 36.25 | 12 | 17 | - | 11.5 | - | 13 | - | 16 | - | 19 | - | - | - | - |

| 40 | 38.75 | 41.25 | 17 | 22 | 11.75 | 18 | - | 13 | - | 16 | - | 19 | - | - | - | - |

| 45 | 43.75 | 46.25 | 22 | 27 | 16.75 | 23 | 11.5 | 19 | - | 16 | - | 19 | - | - | - | - |

| 50 | 48.75 | 51.25 | 27 | 32 | 21.75 | 28 | 16.5 | 24 | 11.25 | 20 | - | 19 | - | 24 | - | - |

| 55 | 53.50 | 56.50 | 32 | 37 | 26.75 | 33 | 21.5 | 29 | 16.25 | 25 | - | 19 | - | 24 | - | - |

| 60 | 58.5 | 61.5 | 37 | 42 | 31.75 | 38 | 26.5 | 34 | 21.25 | 30 | - | 19 | - | 24 | - | 28 |

| 65 | 63.5 | 66.5 | 42 | 47 | 36.75 | 43 | 31.5 | 39 | 26.25 | 35 | 17 | 27 | - | 24 | - | 28 |

| 70 | 68.5 | 71.5 | 47 | 52 | 41.75 | 48 | 36.5 | 44 | 31.25 | 40 | 22 | 32 | - | 24 | - | 28 |

| 80 | 78.5 | 81.5 | 57 | 62 | 51.75 | 58 | 46.5 | 54 | 41.25 | 50 | 32 | 42 | 21.5 | 34 | - | 28 |

| 90 | 88.25 | 91.75 | 67 | 72 | 61.75 | 68 | 56.5 | 64 | 51.25 | 60 | 42 | 52 | 31.5 | 44 | 21 | 36 |

| 100 | 98.25 | 101.75 | 77 | 82 | 71.75 | 78 | 66.5 | 74 | 61.25 | 70 | 52 | 62 | 41.5 | 54 | 31 | 46 |

| 110 | 108.25 | 111.75 | 81.75 | 88 | 76.5 | 84 | 71.25 | 80 | 62 | 72 | 51.5 | 64 | 41 | 56 | ||

| 120 | 118.25 | 121.75 | 91.75 | 98 | 86.5 | 94 | 81.25 | 90 | 72 | 82 | 61.5 | 74 | 51 | 66 | ||

| 130 | 128.00 | 132.00 | 95.75 | 102 | 90.5 | 98 | 85.25 | 94 | 76 | 86 | 65.5 | 78 | 55 | 70 | ||

| 140 | 138.00 | 142.00 | 105.75 | 112 | 100.5 | 108 | 95.25 | 104 | 86 | 96 | 75.5 | 88 | 65 | 80 | ||

| 150 | 148.00 | 152.00 | 115.75 | 122 | 110.5 | 118 | 105.25 | 114 | 96 | 106 | 85.5 | 98 | 75 | 90 | ||

| 160 | 156.00 | 164.00 | 120.5 | 128 | 115.25 | 124 | 106 | 116 | 95.5 | 108 | 85 | 100 | ||||

Note :

Length exceeding 50mm must be graded by steps of 10mm. Intermediate lengths should be avoided wherever possible.

For manufacturing reasons the + IT 15 tolerance is permissible for a length of 2d below head. The shark diameter may also be ≈ pitch diameter at manufacturer discretion.