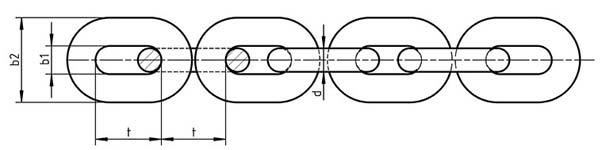

DIN 766 Round steel link chains

Dimensions for DIN 766 Round steel link chains

| d | Pitch | Width | Gauge of length of 11x t | mass | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| t | inside b1 | outside b2 | kg/m | |||||||

| size | Per. Dev. | Permissible deviations | minimum | maximum | Permissible deviations | approx. | ||||

| 4 | ±0.2 | 16 | +0.3 | -0.2 | 4.8 | 13.6 | 176 | +0.8 | -0.4 | 0.32 |

| 5 | ±0.2 | 18.5 | +0.4 | -0.2 | 6 | 17 | 203.5 | +0.9 | -0.5 | 0.5 |

| 6 | ±0.2 | 18.5 | +0.4 | -0.2 | 7.2 | 20.4 | 203.5 | +0.9 | -0.5 | 0.8 |

| 7 | ±0.3 | 22 | +0.4 | -0.2 | 8.4 | 23.8 | 242 | +1.1 | -0.5 | 1.1 |

| 8 | ±0.3 | 24 | +0.4 | -0.2 | 9.6 | 27.2 | 264 | +1.2 | -0.6 | 1.4 |

| 9 | ±0.4 | 27 | +0.5 | -0.3 | 10.8 | 30.6 | 297 | +1.3 | -0.7 | 1.8 |

| 10 | ±0.4 | 28 | +0.5 | -0.3 | 12 | 36 | 308 | +1.4 | -0.7 | 2.3 |

| 11 | ±0.4 | 31 | +0.5 | -0.3 | 13.2 | 40 | 341 | +1.5 | -0.8 | 2.7 |

| 13 | ±0.5 | 36 | +0.6 | -0.3 | 15.6 | 47 | 396 | +1.7 | -0.9 | 3.9 |

| 14 | ±0.5 | 41 | +0.7 | -0.4 | 16.8 | 50 | 451 | +2 | -1 | 4.4 |

| 16 | ±0.6 | 45 | +0.8 | -0.4 | 19.2 | 58 | 495 | +2.2 | -1.1 | 5.8 |

| 18 | ±0.9 | 50 | +0.8 | -0.4 | 21.6 | 65 | 550 | +2.5 | -1.2 | 7.4 |

| 20 | ±1 | 56 | +1 | -0.5 | 24 | 72 | 616 | +2.8 | -1.4 | 9 |

| 23 | ±1.2 | 64 | +1.1 | -0.5 | 27.6 | 83 | 704 | +3.2 | -1.6 | 12 |

| 26 | ±1.3 | 73 | +1.2 | -0.6 | 31.2 | 94 | 803 | +3.6 | -1.8 | 15 |

| 28 | ±1.4 | 78 | +1.3 | -0.6 | 33.6 | 101 | 858 | +3.8 | -2 | 18 |

| 30 | ±1.5 | 84 | +1.4 | -0.7 | 36 | 108 | 924 | +4.2 | -2.1 | 20 |

| 32 | ±1.6 | 90 | +1.5 | -0.7 | 38.4 | 115 | 990 | +4.5 | -2.2 | 23 |

| 36 | ±1.8 | 101 | +1.7 | -0.8 | 43.2 | 130 | 1111 | +5 | -2.5 | 29 |

| 40 | ±2 | 112 | +1.9 | -0.8 | 48 | 144 | 1232 | +5.6 | -2.8 | 35 |

| 42 | ±2.1 | 118 | +2 | -1 | 50 | 151 | 1298 | +5.8 | -3 | 40 |

| Size | Load-bearing capacity | Minimum manufacturing test force | Minimum breaking force | Minimum deflection |

|---|---|---|---|---|

| d | kg | kN | kN | f |

| 4 | 200 | 5 | 8 | 3 |

| 5 | 320 | 8 | 12.5 | 4 |

| 6 | 400 | 10 | 16 | 5 |

| 7 | 630 | 16 | 25 | 6 |

| 8 | 800 | 20 | 32 | 7 |

| 9 | 1000 | 25 | 40 | 7 |

| 10 | 1250 | 32 | 50 | 8 |

| 11 | 1600 | 40 | 63 | 9 |

| 13 | 2000 | 50 | 80 | 11 |

| 14 | 2500 | 63 | 100 | 12 |

| 16 | 3200 | 80 | 125 | 13 |

| 18 | 4000 | 100 | 160 | 15 |

| 20 | 5000 | 125 | 200 | 16 |

| 23 | 6300 | 160 | 250 | 19 |

| 26 | 8000 | 200 | 320 | 22 |

| 28 | 10000 | 250 | 400 | 23 |

| 30 | 11200 | 280 | 450 | 24 |

| 32 | 12500 | 320 | 500 | 26 |

| 36 | 16000 | 400 | 630 | 29 |

| 40 | 20000 | 500 | 800 | 32 |

| 42 | 22400 | 560 | 900 | 34 |

| Mean stress at working load limit |

N/mm2 | 80 |

| Stress at manufacturing test force | N/mm2 | 200 |

| Stress at a specified breakign force | N/mm2 | 320 |

| ation of mean stress at working load limit to stress at manuifacturing test force to stress at a specified breaking force |

1:2,5:4 | |

| Minimum total ultimate elongation | % | 15 min. |

| Deflection | mm | approx. 0.8 d |

| For Size |

|---|