DIN 7964 Slotted inserts

- Scope

- Dimensions

- Technical delivery conditions

- Designation

- Example of application

- Referenced Documents

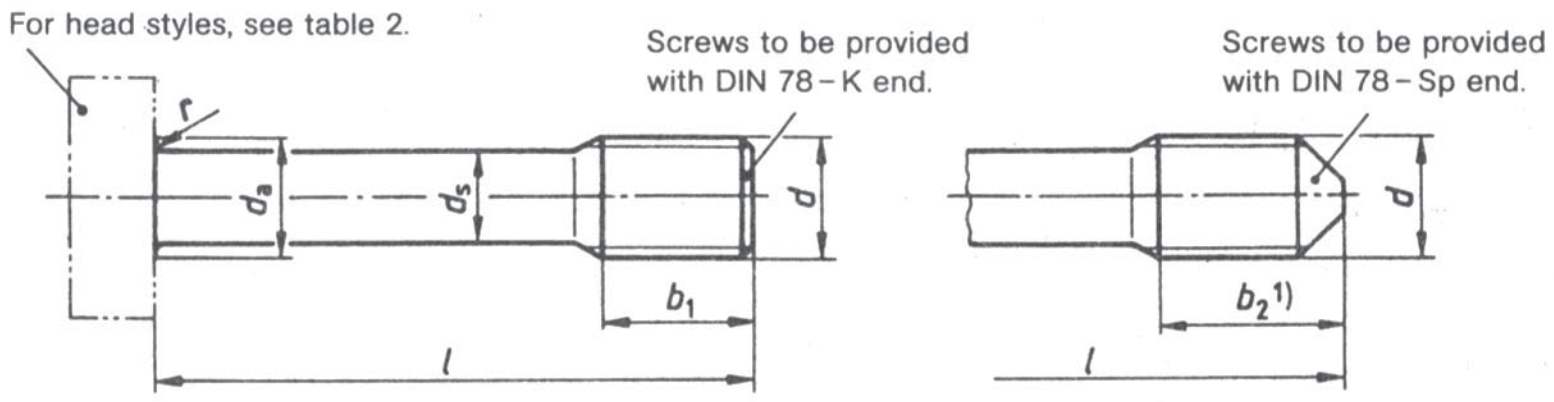

This standard specifies requirements for M 2,5 to M 30 bolts and screws ('bolts', for short) with various

head styles and a diameter of the unthreaded portion of the shank smaller than the minor diameter.

Although such bolts have a reduced shank, they are not waisted shank bolts.

In addition to the head styles adopted from existing DIN Standards (cf. table 2), this standard specifies

two bolt types with different thread lengths, namely type K (with short thread) and type L (with long

thread), each serving a different purpose. Type K is mainly intended for use in cases where the bolt is to

be screwed into a threaded hole of a component (e.g. for fastening a

cover as lid to a housing), while type L is designed for bolt/(hexagon) nut assemblies.

Bolts may be designed as captive fasteners, a snap ring being used, where required (cf clause 5), as a

safeguard to

prevent the screw from working loose.

See DIN 962 (or the standards referred to therein) for special bolt

types or finishes.

Dimensions

1) Dimension b₂ (cf table 1) has been chosen so that the thread length for screws with cone point is equal to that for bolts with chamfered end.

| Thread size(d) | M2,5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M16 | M20 | M24 | M30 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P1) | 0,45 | 0,5 | 0,7 | 0,8 | 1 | 1,25 | 1,5 | 1,75 | 2 | 2,5 | 3 | 3,5 | ||

| b1 + 2/0 P | Type K | 3,2 | 3,8 | 5 | 6,25 | 7,5 | 10 | 12,5 | 15 | 20 | 25 | 30 | 38 | |

| Type L | 10 | 12 | 14 | 16 | 18 | 22 | 26 | 30 | 38 | 46 | 54 | 66 | ||

| b2 + 2/0 P | Type K | 3,75 | 4,5 | 6 | 7,55 | 8,5 | 11,2 | 14,3 | 17,5 | 23 | 28,5 | 33,5 | 43 | |

| Type L | 10,55 | 12,7 | 15 | 17,3 | 19 | 23,2 | 27,8 | 32,5 | 41 | 49,5 | 57,5 | 71 | ||

| da | max. | 3,1 | 3,6 | 4,7 | 5,7 | 6,8 | 9,2 | 11,2 | 13,7 | 17,7 | 22,4 | 26,4 | 33,4 | |

| r | min. | 0,1 | 0,2 | 0,25 | 0,4 | 0,6 | 0,8 | 1 | ||||||

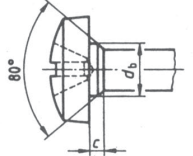

| db2) | max. | 2,5 | 3 | 4 | 5 | 6 | 8 | 10 | -- | -- | -- | -- | -- | |

| min. | 2,36 | 2,86 | 3,82 | 4,82 | 5,82 | 7,78 | 9,78 | -- | -- | -- | -- | -- | ||

| c2) | min. | 0,7 | 0,8 | 1 | 1,3 | 1,5 | 1,9 | 2,4 | -- | -- | -- | -- | -- | |

| max. | 1,2 | 1,3 | 1,5 | 1,8 | 2 | 2,4 | 2,9 | -- | -- | -- | -- | -- | ||

| ds | max. | 1,9 | 2,3 | 3 | 3,9 | 4,6 | 6,2 | 7,7 | 9,2 | 12,7 | 16,2 | 19,2 | 24,2 | |

| min. | 1,7 | 2,1 | 2,8 | 3,7 | 4,4 | 6 | 7,5 | 9 | 12,5 | 16 | 19 | 24 | ||

| Nominal size | l min. | max. | Commerciallly available bolts3) | |||||||||||

| 8 | 7,7 | 8,3 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 10 | 9,7 | 10,3 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 12 | 11,65 | 12,35 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 14 | 13,65 | 14,35 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 16 | 15,65 | 16,35 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 20 | 19,58 | 20,42 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 25 | 24,58 | 25,42 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 30 | 29,58 | 30,42 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 35 | 34,5 | 35,5 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 40 | 39,5 | 40,5 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 45 | 44,5 | 45,5 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 50 | 49,5 | 50,5 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 55 | 54,5 | 55,6 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 60 | 59,4 | 60,6 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 65 | 64,4 | 65,6 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 70 | 69,4 | 70,6 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 80 | 79,4 | 80,6 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 90 | 89,3 | 90,7 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 100 | 99,3 | 100,7 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 110 | 109,3 | 110,7 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 120 | 119,3 | 120,7 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 130 | 129,2 | 130,8 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 140 | 139,2 | 140,8 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 150 | 149,2 | 150,8 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 160 | 159,2 | 160,8 | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

|

Use of thread size given in brackets should be avoided where possible. |

||||||||||||||

| Head style | Illustration | Head dimensions as in | Commercial thread sizes | |

|---|---|---|---|---|

| From | To | |||

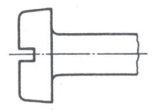

| A |

|

DIN 84 | M2.5 | M10 |

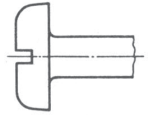

| B |

|

DIN 85 | M3 | M10 |

| C1) |

|

DIN 7985 | M2.5 | M10 |

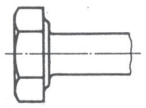

| D12) |

|

ISO 4014 | M3 | M30 |

| D22) | DIN 931 part-1 | M2.5 | M30 | |

| E |

|

DIN 912 | M2.5 | M30 |

| F |

|

DIN 464 | M2.5 | M10 |

|

1) For reinforcement, screws with recessed head are provided with a shoulder at the transition

between head and shank. |

||||

Technical delivery conditions

| Material | Steel | Stainless steel | Non-ferrous metal | |

|---|---|---|---|---|

| General requirements | As specified in DIN 267 Part 1. | |||

| Screw thread | Tolerance | 6g1) | ||

| As specified in | DIN 13 Parts 13 and 15. | |||

| Mechanical properties | Property class (material)2) | 4,8 , 5,6 , 5,8 , 8,8 , or St3) | For sizes up to M20: A2-70 or A4-70; for sizes exceeding M20: A2-50 or A4-50 |

CuZn = Copper-zinc alloy4) |

| As specified in | ISO 898 Part 1 | DIN 267 Part 11 | DIN 267 Part 18 | |

| Limit deviations and geometrical tolerances | Product grade | A | ||

| As specified in | ISO 4759 Part 1 | |||

| Bolts of type and finish requiring additional specifications to be given when ordering | As specified in DIN 962 | |||

| Surface finish | As processed Property class 8.8 (thermally or chemically) blackened. | Bright | Bright | |

| DIN 267 Part 2 shall apply with regard to

surface roughness. DIN 267 Part 19 shall apply with regard to permissible surface discontinuities. DIN 267 Part 9 shall apply with regard to electroplating, any other type of surface protection being subject to agreement. |

||||

| Acceptance inspection | DIN 267 Part 5 shall apply with regard to acceptance inspection. | |||

|

1) Only for screws without surface protection, the 6g tolerance makes it possible for normal

coating thicknesses to be applied in accordance with DIN

267 Part 9 the reference line not being

exceeded.Depending on the coating thickness required a larger fundamental deviation shall be

selected than

that for the g position. This might, however impair the resistance to stripping

of the bolt/nut assembly. |

||||

Designation

The designation of bolts and screws as specified in this standard shall in the following order consist of:

a) the name of product;

b) the IN number;

c) the thread size;

d) the nominal length;

e) the thread length (referring to either type K or L);

f) the symbol denoting the head style (as in table 2);

g) the symbol denoting the type of thread end (as in DIN 78);

h) the property class or material;

l) any further details (eg type of cross recess):

Designation of an M5 bolt with reduced shank and short thread (K) of nominal length, I = 20 mm, head style

C, thread end K, property class 4.8 and cross recess type Z.

Bolt DIN 7964 - M5 × 20 - KC - K - 4,8 - Z

Designation of an M5 bolt with reduced shank and long thread (L) of nominal length, l = 20 mm, head style D1, thread end Sp and property class 8,8:Bolt DIN 7964 - M5 × 20 - LD1 - Sp - 8,8

DIN 962 shall apply for the designation of special features, with additional information to be given on ordering.Example of application

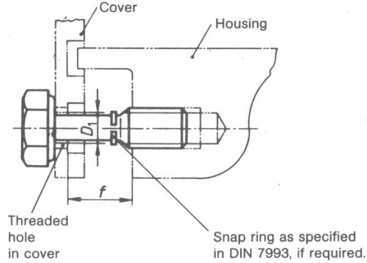

The example given below shows a cover/housing assembly where the captivity of the bolt is ensured by means

of a snap ring and a threaded hole in the cover.

Note - Screws with style C head cannot be used for covers with thread because of the shoulder below the

screw head.

| Thread size(d) | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M16 | M20 | M24 | M30 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D11) min | 2,2 | 2,7 | 3,5 | 4,5 | 5,3 | 7,2 | 9 | 10,8 | 14,7 | 18,3 | 22 | 27,7 |

| f2) min | 5,5 | 6 | 9 | 11 | 13 | 17 | 20 | 23 | 30 | 40 | 46 | 56 |

|

1) Larger than normal minor diameter of thread in cover. |

||||||||||||

Referenced Documents

DIN 13 Part 13 ISO metric screw threads series of preferred sizes for

screws, bolts and nuts from 1 mm to 52 mm diameter

and limits of size.

DIN 13 Part 15 ISO metric screw threads fundamental deviations and

tolerances for screw threads of 1 mm

diameter and larger.

DIN 78 Thread ends and lengths of projection of bolt ends for ISO

metric screw threads in accordance with DIN 13 .

DIN 84 Slotted cheese head screws

DIN 85 Slotted pan head screws

DIN 267 Part 1 Fasteners, technical delivery conditions general

requirements

DIN 267 Part 2 Fasteners technical delivery conditions design and

dimensional accuracy

DIN 267 Part 5 Fasteners, technical delivery

conditions, acceptance inspection (modified version of ISO 3269 1984

edition)

DIN 267 Part 9 Fasteners technical delivery conditions, electroplated

parts

DIN 267 Part 11 Fasteners technical delivery conditions with

addenda to ISO 3506 stainless and acid resistant steer components

DIN 267 Part 18 Fasteners technical delivery conditions nonferrous

metal components

DIN 267 Part 19 Fasteners technical delivery conditions surface

discontinuities on bolts

DIN 464 Knured thumb screws

DIN 912 Hexagon socket nead cap screws (modified version of ISO 4762)

DIN 931 Part 1 M 1,6 to M 39 hexagon head bolls product grades A and

B

DIN 962 Bolts screws studs and nuts designation of types and

finishes

DIN 1651 Free cutting steel technical delivery conditions

DIN 7985 Cross recessed raised cheese head screws

DIN 7993 Round wire snap rings and snap ring grooves for shafts and

bores

ISO 272 Fasteners hexagon products widths across flats

ISO 898 Part 1 Mechanical properties of fasteners bolts,screws and

studs

IS0-4014 Hexagon head boits: product grades A and B

IS0 4759 Part 1 Tolerances for fasteners bolts screws and nuts

with thread diameters from 1.6 to 150 mm

product grades A

Band C