ISO 10684 Specification

Surface areas of bolts, screws and nuts

GeneralThis annex gives guidance for the evaluation of the surface areas of bolts, screws and nuts which are needed for the determination of the batch average thickness according to 8.3.

NOTE The surface areas given in Tables D.1 and D.2 apply only if agreed upon between the parties concerned.

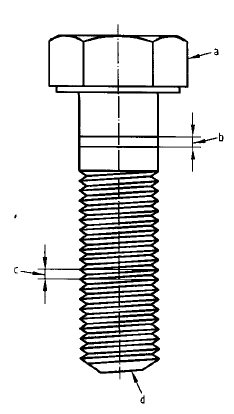

Bolts and screwsTo obtain the total surface area of a bolt or screw, the following parameter values are necessary(see Figure 0.1):

the surface area, A1, of a length of 1 mm of the threaded shank of the bolt or screw;

the surface area, A2, of a length of 1 mm of the unthreaded shank of the bolt or screw;

the surface area, A3, of the head (including surface of the end face).

The total surface areas, A, is then calculated as follows:

A = A1 x thread length + A2 x shank length + A3

a) Total surface area of the head including surface area of the end face,

seed.

b) Surface area of the shank of 1 mm length.

c) Surface area of the threaded part of 1 mm length.

d) Surface area of the end face is included in the surface area of the head

(A3).

Surface area

If the thread is cut, the unthreaded shank will be approximately equal to the basic major

diameter (nominal diameter). If the thread is rolled, the unthreaded shank will be

approximately equal to either the pitch diameter (reduced shank) or the basic major

diameter (full shank).

Table below gives values for the surface areas A1, A 2 and

A3 for different shanks and hexagon

head.

| Thread size(coarse thread) | Surface area per millimetre length | Surface area of head, A3 | ||

|---|---|---|---|---|

| Treaded shank, A 1(coarse thread) | Unthreaded Shank, A2 | Hexagon head | ||

| Full shank | Reduced shank (coarse thread) |

|||

| M8 | 38.48 | 25.15 | 22.43 | 541.3 |

| M10 | 48.31 | 31.42 | 28.17 | 905.8 |

| M12 | 58.14 | 37.63 | 33.98 | 1 151 |

| M14 | 67.97 | 43.99 | 39.45 | 1523 |

| M16 | 78.69 | 50.27 | 45.67 | 1830 |

| M18 | 87.63 | 56.54 | 50.88 | 2 385 |

|

Note For the time being, values for bolts and screws with sizes> M18 or with fine pitch thread are not available and should be calculated as appropriate. |

||||

Table below gives the surface areas of hexagon nut style 1.

NOTE When evaluating the surface area of a hot dip galvanized nut, the surface area of the

thread is not taken into consideration since the nut is tapped after hot dip galvanizing.

| Thread size | Surface area A |

|||

|---|---|---|---|---|

| M8 | 536 | |||

| M10 | 892 | |||

| M12 | 1169 | |||

| M14 | 1522 | |||

| M16 | 1877 | |||

| M18 | 2424 | |||

|

NOTE:-For the time being values for nuts with sizes > M18 and nuts of style 2 are not available and should be calculated as appropriate. |

||||