ISO 4035 Hexagon Thin Nuts Chamfered

ISO 4035 Scope

This International Standard specifies the characteristics of chamfered hexagon thin nuts, with threads

from M1,6 up to and including M64, with product grade A for threads d < M16 and product grade B for

threads d> M16.

If in special cases, specifications other than those listed in this International Standard are

required, they should be

selected from existing International Standards, for example

ISO 724,

ISO 898-2,

ISO 965-1,

ISO 3506-2

and ISO 4759-1.

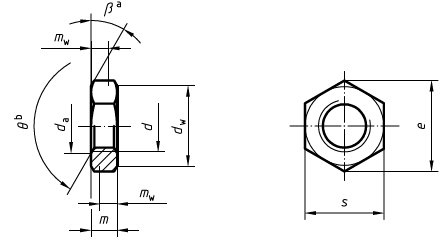

a β=15° to 30°.

b θ=110° to 120°.

ISO 4035 Hexagon Thin Nuts Dimensions

| Thread D |

pa | da | dw | e | m | mw | s | |||

|---|---|---|---|---|---|---|---|---|---|---|

| max. | min. | min. | min. | max. | min. | min. | nom. = max. | min. | ||

| M1.6 | 0.35 | 1.84 | 1.60 | 2.40 | 3.41 | 1.00 | 0.75 | 0.60 | 3.20 | 3.02 |

| M2 | 0.4 | 2.30 | 2.00 | 3.10 | 4.32 | 1.20 | 0.95 | 0.80 | 4.00 | 3.82 |

| M2.5 | 0.45 | 2.90 | 2.50 | 4.1 | 5.45 | 1.60 | 1.35 | 1.10 | 5.00 | 4.82 |

| M3 | 0.5 | 3.45 | 3.00 | 4.60 | 6.01 | 1.80 | 1.55 | 1.20 | 5.50 | 5.32 |

| M3.5 | 0.6 | 4.00 | 3.50 | 5.10 | 6.58 | 2.00 | 1.75 | 1.40 | 6.00 | 5.82 |

| M4 | 0.7 | 4.60 | 4.00 | 5.90 | 7.66 | 2.20 | 1.95 | 1.60 | 7.00 | 6.78 |

| M5 | 0.8 | 5.75 | 5.00 | 6.90 | 8.79 | 2.70 | 2.45 | 2.00 | 8.00 | 7.78 |

| M6 | 1 | 6.75 | 6.00 | 8.90 | 11.05 | 3.20 | 2.90 | 2.3 | 10.00 | 9.78 |

| M8 | 1.25 | 8.75 | 8.00 | 11.60 | 14.38 | 4.00 | 3.70 | 3.0 | 13.00 | 12.73 |

| M10 | 1.5 | 10.80 | 10.00 | 14.60 | 17.77 | 5.00 | 4.70 | 3.8 | 16.00 | 15.73 |

| M12 | 1.75 | 13.00 | 12.00 | 16.60 | 20.03 | 6.00 | 5.70 | 4.60 | 18.00 | 17.73 |

| M14 | 2 | 15.10 | 14.00 | 19.60 | 23.36 | 7.00 | 6.42 | 5.10 | 21.00 | 20.67 |

| M16 | 2 | 17.30 | 16.00 | 22.50 | 26.75 | 8.00 | 7.42 | 5.90 | 24.00 | 23.67 |

| M18 | 2.5 | 19.50 | 18.00 | 24.90 | 29.56 | 9.00 | 8.42 | 6.70 | 27.00 | 26.16 |

| M20 | 2.5 | 21.60 | 20.00 | 27.70 | 32.95 | 10.00 | 9.10 | 7.30 | 30.00 | 29.16 |

| M22 | 2.5 | 23.70 | 22.00 | 31.40 | 37.29 | 11.00 | 9.90 | 7.90 | 34.00 | 33.00 |

| M24 | 3 | 25.90 | 24.00 | 33.20 | 39.55 | 12.00 | 10.90 | 8.70 | 36.00 | 35.00 |

| M27 | 3 | 29.10 | 27.00 | 38.00 | 45.20 | 13.50 | 12.40 | 9.90 | 41.00 | 40.00 |

| M30 | 3.5 | 32.40 | 30.00 | 42.80 | 50.85 | 15.00 | 13.90 | 11.10 | 46.00 | 45.00 |

| M33 | 3.5 | 35.60 | 33.00 | 46.60 | 55.37 | 16.50 | 15.40 | 12.30 | 50.00 | 49.00 |

| M36 | 4 | 38.90 | 36.00 | 51.10 | 60.79 | 18.00 | 16.90 | 13.50 | 55.00 | 53.80 |

| M39 | 4 | 42.10 | 39.00 | 55.90 | 66.44 | 19.50 | 18.20 | 14.60 | 60.00 | 58.80 |

| M42 | 4.5 | 45.40 | 42.00 | 60.00 | 71.39 | 21.00 | 19.70 | 15.80 | 65.00 | 63.10 |

| M45 | 4.5 | 48.00 | 45.00 | 64.70 | 76.95 | 22.50 | 21.20 | 17.00 | 70.00 | 68.10 |

| M48 | 5 | 51.80 | 49.00 | 69.50 | 82.60 | 24.00 | 22.70 | 18.20 | 75.00 | 73.10 |

| M52 | 5 | 56.20 | 52.00 | 74.20 | 88.25 | 26.00 | 24.70 | 19.80 | 80.00 | 78.10 |

| M56 | 5.5 | 60.50 | 56.00 | 78.70 | 93.56 | 28.00 | 26.70 | 21.40 | 85.00 | 82.80 |

| M60 | 5.5 | 64.80 | 60.00 | 83.40 | 99.21 | 30.00 | 28.70 | 23.00 | 90.00 | 87.80 |

| M64 | 6 | 69.10 | 64.00 | 88.20 | 104.86 | 32.00 | 30.40 | 24.30 | 95.00 | 92.80 |

ISO 4035 Hexagon Thin Nuts Weight Chart

| Size | Weight |

|---|---|

| M1.6 | 0.06 |

| M1.8 | 0.08 |

| M2 | 0.11 |

| M2.5 | 0.22 |

| M3 | 0.29 |

| M3.5 | 0.37 |

| M4 | 0.57 |

| M5 | 0.83 |

| M6 | 1.60 |

| M8 | 3.20 |

| M10 | 7.20 |

| M12 | 10.4 |

| M14 | 15.9 |

| M16 | 20.5 |

| M18 | 29.6 |

| M20 | 40.2 |

| M22 | 48.3 |

| M24 | 69.5 |

| M27 | 101 |

| M30 | 139 |

| M33 | 183 |

| M36 | 244 |

| M39 | 316 |

| M42 | 403 |

| M45 | 500 |

| M48 | 617 |

| M52 | 755 |

ISO 4035 Technical Delivery Conditions

| Material | Steel | Stainless steel | Non-ferrous metal |

|

|---|---|---|---|---|

| General requirements |

International standard | ISO 8992 | ||

| Thread | Tolerance class | 6H | ||

| International Standards | ISO 724, ISO 965-1 | |||

| Mechanical properties |

Property class | D

< M5: as agreed M5 ≤ D ≤ M39: 04, 05 D > M39: as agreed |

D ≤ M24: A2-035, A4-035 M24 < D ≤ M39: A2-025, A4-025 D > M39: as agreed |

Material specified in ISO 8839 |

| International Standards | D

< M5: as agreed M5 ≤ D ≤ M39: ISO 898-2 D > M39: as agreed(specified in ISO 898-2:2012, Annex A) |

D ≤ M39: ISO 3506-2 D > M39: as agreed |

||

| Tolerance | Product grade | D ≤ M16: A D > M16: B |

||

| International Standards | ISO 4759-1 | |||

| Finish Coating | As processed | Clean and bright | As processed | |

| Requirements for electroplating are specified in ISO 4042. | A method for passivation is specified in ISO 16048. | Requirements for electroplating are specified in ISO 4042. | ||

| Requirements for non-electrolytically applied zinc flake coatings are specified in ISO 10683. | ||||

| Requirements for hot dip galvanized coatings are specified in ISO 10684. | ||||

| Additional requirements or other finishes or coatings shall be agreed between the supplier and the purchaser. | ||||

| Surface integrity | Limits for surface discontinuities are specified in ISO 6157-2 | |||

| Acceptablity | Acceptance inspection is specified in ISO 3269 | |||

ISO 4035 Reference Standards

| Standards | Reference |

|---|---|

| ISO 225 | Fasteners — Bolts, screws, studs and nuts — Symbols and designations of dimensions. |

| ISO 724 | ISO general-purpose metric screw threads — Basic dimensions. |

| ISO 898-2 | ISO general-purpose metric screw threads — Basic dimensions. |

| ISO 965-1 | ISO general purpose metric screw threads — Tolerances — Part 1: Principles and basic data. |

| ISO 3269 | Fasteners — Acceptance inspection. |

| ISO 3506-2 | Mechanical properties of corrosion-resistant stainless steel fasteners — Part 2: Nuts. |

| ISO 4042 | Fasteners — Electroplated coatings. |

| ISO 4759-1 | Tolerances for fasteners — Part 1: Bolts, screws, studs and nuts — Product grades A, B and C. |

| ISO 6157-2 | Fasteners — Surface discontinuities — Part 2: Nuts. |

| ISO 8839 | Mechanical properties of fasteners — Bolts, screws, studs and nuts made of non-ferrous metals. |

| ISO 8992 | Fasteners — General requirements for bolts, screws, studs and nuts. |

| ISO 16083 | Fasteners — Non-electrolytically applied zinc flake coatings. |

| ISO 10684 | Fasteners -- Hot dip galvanized coatings. |