ISO 4672 Hexagon Socket Head Cap Screws (Metric)

- Scope

- Dimensions

- Specifications and reference International Standards

- Designation

- Requirements and reference International Standards

- Designation

- Reference Documents

ISO 4762 International Standard specifies the characteristics of hexagon socket head cap screws with

threads from Ml.6 up to and including M64 and product grade A.

If, in special cases, specifications other than those listed in this International Standard are required,

they should be selected from existing International Standards, for example

ISO 261,

ISO 888,

ISO 898-1,

ISO 965-2,

ISO 3506-1 and

ISO 4759-1.

Dimensions

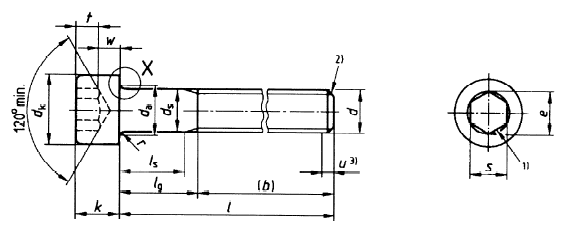

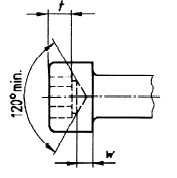

1) A slight rounding or countersink at the mouth of the socket is permissible.

2) Point chamfered or for sizes M4 and below “as rolled”, see ISO

4753.

3) lncomplete thread u ≤ 2 P.

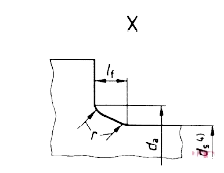

4)ds applies if value of lsmin are specified.

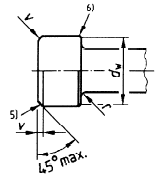

5)Top edge of head may be rounded or chamfered as shown at the discretion of the manufacturer.

6)Bottom edge of head may be rounded or chamfered to dw but in every case must be free from

burrs.

| Thread (d) | p1) | b2) | dk | da | ds | e | lf | k | r | s | t | v | dw | w | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ref | max3 | max4 | min | max | max | min | min5 | max | max | min | min | nom | max6 | max7 | min | min | max | min | min | ||

| M1.6 | 0.35 | 15 | 3.00 | 3.14 | 2.86 | 2 | 1.60 | 1.46 | 1.73 | 0.34 | 1.60 | 1.46 | 0.1 | 1.5 | 1.545 | 1.560 | 1.520 | 0.7 | 0.16 | 2.72 | 0.55 |

| 2 | 0.4 | 16 | 3.80 | 3.98 | 3.62 | 2.6 | 2.00 | 1.86 | 1.73 | 0.51 | 2.00 | 1.86 | 0.1 | 1.5 | 1.545 | 1.560 | 1.520 | 1 | 0.2 | 3.48 | 0.55 |

| 2.5 | 0.45 | 17 | 4.50 | 4.68 | 4.32 | 3.1 | 2.50 | 2.36 | 2.3 | 0.51 | 2.50 | 2.36 | 0.1 | 2 | 2.045 | 2.060 | 2.020 | 1.1 | 0.25 | 4.18 | 0.85 |

| M3 | 0.5 | 18 | 5.50 | 5.68 | 5.32 | 3.6 | 3.00 | 2.86 | 2.87 | 0.51 | 3.00 | 2.86 | 0.1 | 2.5 | 2.56 | 2.58 | 2.52 | 1.3 | 0.3 | 5.07 | 1.15 |

| M4 | 0.7 | 20 | 7.00 | 7.22 | 6.78 | 4.7 | 4.00 | 3.82 | 3.44 | 0.6 | 4.00 | 3.82 | 0.2 | 3 | 3.071 | 3.080 | 3.020 | 2 | 0.4 | 6.53 | 1.4 |

| M5 | 0.8 | 22 | 8.50 | 8.72 | 8.28 | 5.7 | 5.00 | 4.82 | 4.58 | 0.6 | 5.00 | 4.82 | 0.2 | 4 | 4.084 | 4.095 | 4.020 | 2.5 | 0.5 | 8.03 | 1.9 |

| M6 | 1 | 24 | 10.00 | 10.22 | 9.78 | 6.8 | 6.00 | 5.82 | 5.72 | 0.68 | 6.0 | 5.7 | 0.25 | 5 | 5.084 | 5.140 | 5.020 | 3 | 0.6 | 9.38 | 2.3 |

| M8 | 1.25 | 28 | 13.00 | 13.27 | 12.73 | 9.2 | 8.00 | 7.78 | 6.86 | 1.02 | 8.00 | 7.64 | 0.4 | 6 | 6.095 | 6.140 | 6.020 | 4 | 0.8 | 12.33 | 3.3 |

| M10 | 1.5 | 32 | 16.00 | 16.27 | 15.73 | 11.2 | 10.00 | 9.78 | 9.15 | 1.02 | 10.00 | 9.64 | 0.4 | 8 | 8.115 | 8.175 | 8.025 | 5 | 1 | 15.33 | 4 |

| M12 | 1.75 | 36 | 18.00 | 18.27 | 17.73 | 13.7 | 12.00 | 11.73 | 11.43 | 1.45 | 12.00 | 11.57 | 0.6 | 10 | 10.115 | 10.175 | 10.025 | 6 | 1.2 | 17.23 | 4.8 |

| (M14)8 | 2 | 40 | 21.00 | 21.33 | 20.67 | 15.7 | 14.00 | 13.73 | 13.72 | 1.45 | 14.00 | 13.57 | 0.6 | 12 | 12.142 | 12.212 | 12.032 | 7 | 1.4 | 20.17 | 5.8 |

| M16 | 2 | 44 | 24.00 | 24.33 | 23.67 | 17.7 | 16.00 | 15.73 | 16 | 1.45 | 16.00 | 15.57 | 0.6 | 14 | 14.142 | 14.212 | 14.032 | 8 | 1.6 | 23.17 | 6.8 |

| M20 | 2.5 | 52 | 30.00 | 30.33 | 29.67 | 22.4 | 20.00 | 19.67 | 19.44 | 2.04 | 20.00 | 19.48 | 0.8 | 17 | 17.23 | 17.05 | 10 | 2 | 28.87 | 8.6 | |

| M24 | 3 | 60 | 36.00 | 36.39 | 35.61 | 26.4 | 24.00 | 23.67 | 21.73 | 2.04 | 24.00 | 23.48 | 0.8 | 19 | 19.275 | 19.065 | 12 | 2.4 | 34.81 | 10.4 | |

| M30 | 3.5 | 72 | 45.00 | 45.39 | 44.61 | 33.4 | 30.00 | 29.67 | 25.15 | 2.89 | 30.00 | 29.48 | 1 | 22 | 22.275 | 22.065 | 15.5 | 3 | 43.61 | 13.1 | |

| M36 | 4 | 84 | 54.00 | 54.46 | 53.54 | 39.4 | 36.00 | 35.61 | 30.85 | 2.89 | 36.00 | 35.38 | 1 | 27 | 27.275 | 27.065 | 19 | 3.6 | 52.54 | 15.3 | |

| M42 | 4.5 | 96 | 63.00 | 63.46 | 62.54 | 45.6 | 42.00 | 41.61 | 36.57 | 3.06 | 42.00 | 41.38 | 1.2 | 32 | 32.33 | 32.08 | 24 | 4.2 | 61.34 | 16.3 | |

| M48 | 5 | 108 | 72.00 | 72.46 | 71.54 | 52.6 | 48.00 | 47.61 | 41.13 | 3.91 | 48.00 | 47.38 | 1.6 | 36 | 36.33 | 36.08 | 28 | 4.8 | 70.34 | 17.5 | |

| M56 | 5.5 | 124 | 84.00 | 84.54 | 83.46 | 63 | 56.00 | 55.54 | 46.83 | 5.95 | 56.00 | 55.26 | 2 | 41 | 41.33 | 41.08 | 34 | 5.6 | 82.26 | 19 | |

| M64 | 6 | 140 | 96.00 | 96.54 | 96.46 | 71 | 64.00 | 63.54 | 52.53 | 5.95 | 64.00 | 63.26 | 2 | 46 | 46.33 | 46.08 | 38 | 6.4 | 94.26 | 22 | |

|

1. p is the pitch of the thread. |

|||||||||||||||||||||

| l9 | Shank length ls and grip Length ls | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread (d) | ls | lg | ls | lg | ls | lg | ls | lg | ls | lg | ls | lg | ls | lg | ls | lg | ||

| nom. | min. | max. | min. | max. | min. | max. | min. | max. | min. | max. | min. | max. | min. | max. | min. | max. | min. | max. |

| M2.5 | 2.3 | 2.7 | ||||||||||||||||

| M3 | 2.8 | 3.2 | ||||||||||||||||

| M4 | 3.76 | 4.24 | ||||||||||||||||

| M5 | 4.76 | 5.24 | ||||||||||||||||

| M6 | 5.76 | 6.24 | ||||||||||||||||

| M8 | 7.71 | 8.29 | ||||||||||||||||

| M10 | 9.71 | 10.29 | ||||||||||||||||

| M12 | 11.65 | 12.35 | ||||||||||||||||

| M16 | 15.65 | 16.35 | ||||||||||||||||

| M20 | 19.58 | 20.42 | 2 | 4 | ||||||||||||||

| M25 | 24.58 | 25.42 | 5.75 | 8 | 4.5 | 7 | ||||||||||||

| M30 | 29.58 | 30.42 | 9.5 | 12 | 6.5 | 10 | 4 | 8 | ||||||||||

| M35 | 34.5 | 35.5 | 11.5 | 15 | 9 | 13 | 6 | 11 | ||||||||||

| M40 | 39.5 | 40.5 | 16.5 | 20 | 14 | 18 | 11 | 16 | 5.75 | 12 | ||||||||

| M45 | 44.5 | 45.5 | 5.5 | 13 | 19 | 23 | 16 | 21 | 10.75 | 17 | ||||||||

| M50 | 49.5 | 50.5 | 10.5 | 18 | 24 | 28 | 21 | 26 | 15.75 | 22 | ||||||||

| M55 | 54.4 | 55.6 | 15.5 | 23 | 10.25 | 19 | 26 | 31 | 20.75 | 27 | ||||||||

| M60 | 59.4 | 60.6 | 20.5 | 28 | 15.25 | 24 | 10 | 20 | 31 | 36 | 25.75 | 32 | ||||||

| M65 | 64.4 | 65.6 | 25.5 | 33 | 20.25 | 29 | 15 | 25 | 11 | 21 | 30.75 | 37 | ||||||

| M70 | 69.4 | 70.6 | 30.5 | 38 | 25.25 | 34 | 20 | 30 | 16 | 26 | 35.75 | 42 | ||||||

| M80 | 79.4 | 80.6 | 40.5 | 48 | 35.25 | 44 | 30 | 40 | 26 | 36 | 15.5 | 28 | 45.75 | 52 | ||||

| M90 | 89.3 | 90.7 | 50.5 | 58 | 45.25 | 54 | 40 | 50 | 36 | 46 | 25.5 | 38 | 15 | 30 | ||||

| M100 | 99.3 | 100.7 | 60.5 | 68 | 55.25 | 64 | 50 | 60 | 46 | 56 | 35.5 | 48 | 25 | 40 | ||||

| M110 | 109.3 | 110.7 | 65.25 | 74 | 60 | 70 | 56 | 66 | 45.5 | 58 | 35 | 50 | 20.5 | 38 | ||||

| M120 | 119.3 | 120.7 | 75.25 | 84 | 70 | 80 | 66 | 76 | 55.5 | 68 | 45 | 60 | 30.5 | 48 | 16 | 36 | ||

| M130 | 129.2 | 130.8 | 80 | 90 | 76 | 86 | 65.5 | 78 | 55 | 70 | 40.5 | 58 | 26 | 46 | ||||

| M140 | 139.2 | 140.8 | 21.5 | 44 | 90 | 100 | 86 | 96 | 75.5 | 88 | 65 | 80 | 50.5 | 68 | 36 | 56 | ||

| M150 | 149.2 | 150.8 | 31.5 | 54 | 96 | 106 | 85.5 | 98 | 75 | 90 | 60.5 | 78 | 46 | 66 | ||||

| M160 | 159.2 | 160.8 | 41.5 | 64 | 27 | 52 | 106 | 116 | 95.5 | 108 | 85 | 100 | 70.5 | 88 | 56 | 76 | ||

| M180 | 179.2 | 180.8 | 61.5 | 84 | 47 | 72 | 28.5 | 56 | 115.5 | 128 | 105 | 120 | 90.5 | 108 | 76 | 96 | ||

| M200 | 199.075 | 200.925 | 81.5 | 104 | 67 | 92 | 48.5 | 76 | 30 | 60 | 135.5 | 148 | 125 | 140 | 110.5 | 128 | 96 | 116 |

| M220 | 219.075 | 220.925 | 101.5 | 124 | 87 | 112 | 68.5 | 96 | 50 | 80 | ||||||||

| M240 | 239.075 | 240.925 | 121.5 | 144 | 107 | 132 | 88.5 | 116 | 70 | 100 | ||||||||

| M260 | 258.95 | 261.05 | 141.5 | 164 | 127 | 152 | 108.5 | 136 | 90 | 120 | ||||||||

| M280 | 278.95 | 281.05 | 161.5 | 184 | 147 | 172 | 128.5 | 156 | 110 | 140 | ||||||||

| M300 | 298.95 | 301.05 | 181.5 | 204 | 167 | 192 | 148.5 | 176 | 130 | 160 | ||||||||

|

9. The range of commercial length is between the thick stepped lines. Length above the dashed

stepped line are threaded to the head within 3 p. Lenght below the dashed stepped lines have

values of lg and ls in accordance with the following formulae: |

||||||||||||||||||

Requirements and reference International Standards

| Material | Steel | Stainless Steel | Non-ferrous metal | |

|---|---|---|---|---|

| General requirements | International Standard | ISO 8992 | ||

| Thread | Tolerance | 5g6g for property class 12.9; for other property classes: 6g | ||

| International Standards | ISO 261 , ISO 965-2 , ISO 965-3 | |||

| Mechanical Properties | Property class |

< M3: as agreed ≥ M3 and ≤ M39: 8.8, 10.9, 12.9 > M39: as agreed |

≤ M24: A2-50, A2-702) >M24 and ≤ M39: A2-50, A4-50 2) > M39: as agreed |

all defined materials |

| International Standards | ISO 898-11) | ISO 3506-1 | ISO 8839 | |

| Tolerance | Product grade | A | ||

| International Standards | ISO 4759-1 | |||

| Finish | Black oxide (thermal or chemical) |

Plain | Plain | |

|

Requirements for electroplating are covered in ISO 4042 |

-- |

Requirements for electroplating are covered in ISO 4042 |

||

|

If different electroplsting requirements are dsired or if requirements are needed for other finishes, they shall be agreeed between customer and supplier. |

||||

|

Limits for surface discontinuous are cover in ISO 6157-1 and ISO 6157-3 |

||||

| Acceptability | Acceptance procedure is covered in ISO 3269 | |||

|

1) For Screws unsuitable for tensile testing, the hardness requirements shall be fulfilled throughtouyt the section of the screw. 2) For Stainless stell screws machined from bar it is permissible to use garde A1-70 for sizes ≤ M12 and A1-50 for sizes > M12 but they should be marked according to their property class. |

||||

Designation

A hexagon socket head cap screw with thread M5, nominal length l = 20 mm and property class 12.9 is

designated as follows:

Hexagon socket head cap screw ISO 4762 - M5 X 20 -

12.9

Reference Documents

ISO 225: 1983, Fasteners-- Bolts, screws, studs and nuts -- Symbol and designation of dimensions.

ISO 261: 1973, ISO general purpose metric screw threads -- General plan

ISO 888: 1976, Bolts screws and nuts- Nominal lengths, and thread lengths for general purpose bolts.

ISO 898-1: 1988, Mechanical properties of fasteners - Part 1: Bolts, screws and studs.

ISO 965-2: 1980, ISO general purpose metric screw threads - Tolerantes - Part 2: Limits of sizes for general purpose bolt and nut threads - Medium quality.

ISO 965-3: 1980, ISO general purpose metric screw threads - Tolerantes - Part 3: Deviations for constructional thread.

ISO 3269: 1988, Fasteners - Acceptance inspection.

ISO 3506-1:1997, Mechanical properties of corrosion-resistant stainless steel fasteners - part 1: Bolts, screws and studs.

ISO 4042:1989, Fasteners - Electroplated coating.

ISO 4753:1989, Fasteners - Ends of parts with external metric ISO threads.

ISO 4759-1:1978, Tolerantes for fasteners - Part 1: Bolts, screws and nuts - product grades A, B and C

ISO 6157-1:1988, Fasteners - Surface discontinuities - Part 1: Bolts, screws and studs for general requirements.

ISO 6157-3:1988, Fasteners - Surface discontinuities - Part 3: Bolts, screws and studs for special requirements.

ISO 8839:1986, Mechanical properties of fasteners - Bolts, screws, studs and nuts made of non-ferrous metals.

ISO 8992:1986, Fasteners - General requirements for bolts, screws, studs and nuts.