ASTM A962 Specification

- Scope

- Terminology

- Other Informations

- Melting Process

- Materials And Manufacture

- Chemical Composition

- Mechanical properties

- Hardness Requirements

- Tensile Requirements

- Proof Load and Cone Proof Requirements

- Impact Requirements

- Cone Proof Load Using 120° Hardened Steel Cone—InchA

- Workmanship, Finish, and Appearance

- Decarburization

- Number of Tests

- Retest And Rework

- Inspection

- Rejection and Rehearing

- Packaging, Package Marking and Loading for Shipment

- Supplementary Requirements

- Referenced Documents

This specification covers a group of common requirements that shall apply to carbon, alloy, stainless steel, and nickel alloy bolting under any of the following ASTM Specifications (or under any other ASTM Specifications that invoke this specification or portions thereof):

| Title of Specifications | ASTM Designation |

|---|---|

| Alloy-Steel and Stainless Steel Bolting Materials for High-Temperature Service | A193/A193M |

| Carbon and Alloy Steel Nuts for Bolts for High Pressure and High-Temperature Service | A194/A194M |

| Alloy Steel Bolting Materials for Low-Temperature Service | A320/A320M |

| Alloy-Steel Turbine-Type Bolting Material Specially Heat Treated for High-Temperature Service | A437/A437M |

| High-Temperature Bolting Materials With Expansion Coefficients Comparable to Austenitic Stainless Steels | A453/A453M |

| Alloy-Steel Bolting Materials for Special Applications | A540/A540M |

| Precipitation-Hardening Bolting Material (UNS N07718) for High Temperature Service | A1014/A1014M |

In case of conflict, the requirements of the individual product specification shall prevail over those of this specification.

Fasteners are a wide-ranging classification that includes screws, bolts, nuts, washers, stud bolts, rivets, powder-actuated studs, staples, tacks, and pins. Bolting, which is composed of bolting materials, such as rods, bars, flats, and forgings, which are subsequently manufactured into bolting components, are a special sub-group of fasteners. Bolting materials and components have designated compositions and specific properties intended for applications in aggressive service where commercial generic fasteners may not be suitable or have insufficient fitness for purpose under certain conditions. These conditions include cryogenic or high temperature service, or excessive vibration, impact, or shock. To further address any other special service conditions where bolting is intended for use, additional requirements may be specified by mutual agreement between the purchaser and supplier.

Supplementary requirements are provided for use at the option of the purchaser. The supplementary requirements only apply when specified individually by the purchaser in the purchase order or contract.

This specification is expressed in both inch-pound units and in SI units. Unless the purchase order or contract specifies the applicable “M” specification designation (SI units) the inch-pound units shall apply. The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

Terminology

Definitions of Terms Specific to This Standard:

- bar—a solid rolled or forged section that is long in relationship to its cross-sectional dimensions

with a relatively constant cross section throughout its length.

See A29/A29M for definitions relating to the production of hot wrought and cold finished bars. - bolting—a general term which includes bolting materials (rolled or forged bars or blanks, wire, rod, threaded bar, rotary pierced or extruded seamless tubes, bored bars, or forged hollows from forged or rolled bar segments), which are manufactured into bolting components, including but not limited to, connectors, pins, restraining device components, shafts, bolts, nuts, screws, studs, and washers.

- bolting components—components, such as bolts, nuts, screws, studs, washers, connectors, and pins, are finished products which join, fasten, restrain, or position objects.

- bolting materials—starting materials used for the manufacture of bolting components, such as rolled or forged or threaded solid bars, blanks, wires, rods, or tubes or other hollow sections, that may be further processed by heat treatment, cold working, forging, threading, or machining.

- certifying organization—the company or association responsible for the conformance and marking of the product to the specification requirements.

- class—a term used to differentiate between different heat treatment conditions or strength levels, or both, often within the same grade but sometimes within the same family of materials. May also apply to work hardened condition or strength level, or both.

- grade—an alloy described individually and identified by its own designation in a table of chemical requirements within any specification.

- length, components subject to full size testing—that portion of the bolting component whose body diameter is approximately the same as the nominal thread size.

- bolting, heat treated in batch type furnaces—all bolting material of the same heat or cast of material, condition, finish, and size subjected to the same heat treatment in one tempering charge and submitted for inspection at the same time.

- bolting, heat treated in continuous type furnaces— all bolting material of the same heat or cast of material, condition, finish, and size heat treated without interruption in a continuous type furnace.

- bolting, non heat treated (strain hardened)—all bolting material of the same heat or cast of material, condition, reduction (cold work), finish, and size.

- components, machined from bolting material—all bolting components machined from the same lot of bolting material defined as outlined in either 3.1.9.1 or 3.1.9.2, above without any subsequent heat treatment or hot or cold forming.

- components, heat treated in batch type furnaces—all bolting component items produced by any manufacturing process (such as rolling, forging, or machining) from the same heat or cast of material, of the same prior condition, the same size, and subjected to the same heat treatment in one tempering charge.

- components, heat treated in continuous type furnaces—all bolting component items produced by any manufacturing process (such as rolling, forging, or machining) from the same heat or cast of material, of the same prior condition, of the same size, and then subjected to the same heat treatment in a four hour period and in one tempering charge.

- components, non heat treated (strain hardened)—all bolting components of the same heat or cast of material, condition, reduction (cold work), finish, and size.

- strain hardened material—austenitic stainless steel material which has been subjected to cold working sufficient to cause a significant increase in strength.

- Quantity and size,

- Product specification number with grade, class, type, as applicable, and including the product specification year date,

- Any additional information required by the individual product specification,

- Supplementary requirements,

- Additional requirements (see 5.3, 5.5, 5.6, 6.1, 7.4, 13.1, 13.3.1, 13.3.3, 13.5.2, 13.6, 15.8, and 19.1).

- Additional ordering options provided in the individual product specification, and

- Dimensions (diameter, length of point, overall length, finish, shape, threads, etc.).

- When the dimensions of the component material to be tested will permit, the tension test specimens shall bemachined to the form and dimensions of the standard 2–in. [50–mm] gage length tension test specimen described in Test Methods and Definitions A370.

- When the dimensions of the component material to be tested do not permit full size specimens, small size specimens meeting the requirements of Test Methods and Definitions A370. shall be used.

- Mandrels shall have a hardness of 45 HRC minimum with threads of the appropriate series and conforming to the requirements of ASME B1.1 Class 3A or ASME B1.13M tolerance 4H except that the maximum major diameter shall be the minimum major diameter plus 0.25 times the major diameter tolerance.

- The test bolt shall have threads appropriate to the standard specified for the nut being tested and shall have a yield strength in excess of the specified proof load of the nut being tested.

- The mandrel/tension method shall be used when arbitration is required.

- Mandrels shall conform to the requirements of 11.1.1.

- Conical washers shall have a hardness of 57 HRC minimum and a hole diameter equivalent to the nominal diam1eter of the mandrel +0.002, -0.000 in. [+0.05 and -0.00 mm].

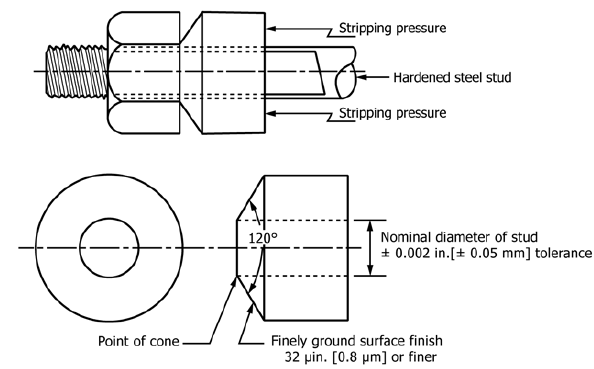

- The contact point of the cone shall be sharp for nut sizes 1⁄2 in. [12 mm] or less. For sizes over 1⁄2 in. [12 mm], the point shall be flat and 0.015 ± 0.001 in. [0.38 + 0.03 mm] in width.

- Cone proof loads may be determined as shown in Tables 1 and 2 when they are not specified in the product specification.

- Hardness Tests, Bar, Rod, or Wire—One test per lot.

- Hardness Tests, Components—The minimum number of bolting components that must be hardness tested per lot, regardless of the manufacturing production process, shall conform to 15.3.

- Macroetch, Carbon and Alloy Steels Only—One test per lot. A lot in this case is defined as a single diameter of a single heat or the largest diameter of a single heat.

- Impact Tests—Three impact test specimens shall be made for each lot when impact testing is required by the product specification.

- Other Tests—The number of tests shall be as specified by the purchaser or the individual product specification.

- The surface discontinuities shall conform to Specification F788/F788M and the additional limitations in S54.2.2.

- Thread lap inspection shall be performed in accordance with Specification F788/F788M Supplementary Requirement S50. The threads shall have no laps at the root, or on the flanks initiating or extending below the pitch line.

- Quench cracks of any depth, any length, or in any location are not permitted.

- Folds at the junction of the head and the shank are not permitted.

- Decarburization tests shall be conducted as follows, with the same number of tests as the tension test:

- Section the thread area longitudinally through the axis, and mount and polish the cut face in accordance with Practice E3. Use either optical or microhardness measurements for decarburization. In case of dispute, the microhardness method shall be used.

- For optical measurement, etch the metallographic section in 4 % Nital. Examine the surface of the etched sample under a microscope at 100× using a measuring eyepiece graduated in 0.001 in. [0.03 mm] increments, or on a ground glass screen or photomicrograph. There shall be no gross decarburization (clearly defined ferrite grains), and the depth of partial decarburization (light etching zone) anywhere below the pitch line shall be less than 5 % of the nominal thread height.

- For microhardness measurement, make hardness tests in accordance with Test Method E384 on unetched metallographic sections using either a DPH 136° indenter and a 200-gf load, or a Knoop indenter and a 200-gf load. Take measurements at the minor diameter on the thread crest bisector to determine the base metal hardness. On the same or an adjacent thread, take measurements within 0.003 in. [0.08 mm] of the flank surface at the pitch line, and 0.003 in. [0.08 mm] below the thread root. These two hardness readings shall be equal to or greater than the base metal hardness minus 30 DPH or KHN.

- Relevant linear indications;

- Relevant rounded indications greater than 3⁄16 in.; and,

- Four or more relevant rounded indications in a line separated by 1⁄16 in. or less, edge to edge.

lot—unless otherwise specified, a lot shall consist of:

Definitions—For definitions of other terms used in this specification, refer to Terminology A941.

Other Informations

It is the purchaser’s responsibility to specify in the purchase order all information necessary to purchase the needed material. Examples of such information include, but are not limited, to the following:

Melting Process

The steel shall be produced by any of the following processes: basic-oxygen, electric-furnace, or vacuuminduction melting (VIM). The molten steel may be vacuumtreated prior to or during pouring of the ingot or strand casting.

Unless otherwise specified in the individual product specification, the steel shall be fully killed. Use of the basic oxygen process shall be limited to grades containing less than 6 % chromium.

If a specific type of melting is required by the purchaser, it shall be stated on the purchase order.

The primary melting may incorporate separate degassing or refining and may be followed by secondary melting such as electroslag remelting or vacuum remelting. If secondary melting is employed, the heat shall be defined as all of the ingot remelted from a single primary heat.

Steel may be cast in ingots or may be continuously cast. When steel of different grades is continuously cast identification of the resultant transition material is required. The steel producer shall remove the transition material by an established procedure that positively separates the grades. Should the purchaser deem it necessary to have the transition zone of two heats of the same grade which are continuously cast discarded, the purchaser shall invoke Supplementary Requirement S53.

Quality—The steel producer quality control procedures shall provide sufficient testing of carbon and alloy steels in accordance with Method E381 or other suitable method as agreed upon between the purchaser and the producer to assure the internal quality of the product.

Ingot Cast Product—Visual examination of transverse sections shall show no imperfections worse than the macrographs of Method E381 S2-R2-C3 or equivalent as agreed upon.

Strand Cast Product—Visual examination of traverse sections in accordance with Method E381 shall reveal none of the conditions shown in macrographs 1-5, 7,12-18 of Plate III. Conditions 6, 8-11 shall not be present to a degree greater than the macrographs of Plates I and II, S2-R2-C3.

Material And Manufacture

Bars shall be produced in accordance with Specifications A29/A29M or A484/A484M as applicable. Finish (hot rolled or cold drawn, rough turned, extruded, ground, or polished) shall be at the option of the manufacturer unless otherwise specified.

A sufficient discard shall be made from each ingot to ensure bars do not contain piping or segregation that precludes use of the product to manufacture bolting meeting the requirements of the individual product specifications.

Bolting components shall be produced in accordance with the product specification.

Chemical Composition

Chemical Analysis—Heat or product chemical analysis shall be in accordance with Test Methods, Practices, and Terminology A751

Heat Analysis—An analysis of each heat of steel shall be made by the steel manufacturer to determine the percentages of those elements specified in the individual product specification. If secondary melting processes are employed, the heat analysis shall be obtained from one remelted ingot or the product of one remelted ingot of each primary melt. The chemical analysis thus determined shall conform to the requirements of the individual product specification. Product analysis (check analysis)tolerances shall not be applied to heat analysis requirements.

Product Analysis—When performed, by manufacturer, purchaser, end user, and so forth, samples for analysis shall be taken from midway between center and surface of solid parts, midway between inner and outer surfaces of hollow parts, midway between center and surface of full-size prolongations or from broken mechanical test specimens. The chemical composition thus determined shall conform to the limits of the product specification, within the permissible tolerances found in Tables 5 and 6 of Specification A29/A29M and Table Below of Specification A484/A484M as appropriate for the grade being supplied. When multiple samples are taken from the same lot for product analysis, individual elements shall not vary both above and below the specified range.

For continuous cast materials the requirements of 8.2 or 8.3, as appropriate, of Specification A788/A788M shall be met.

Steels with intentional additions of lead, bismuth, or tellurium shall not be supplied or used. Steels with intentional additions of selenium may only be supplied or used when specifically called out in the product specification.

The starting material shall not contain any unspecified elements, other than nitrogen in austenitic stainless steels, for the ordered grade(s) to the extent that it then conforms to the requirements of another grade for which that element is a specified element having a required minimum content.

Cone Proof Load Using 120° Hardened Steel Cone—InchA

| Nominal Size, in. | Threads per inch | Stress Area, in.2 | Cone Proof Load, lbf | ||||

|---|---|---|---|---|---|---|---|

| Based on Proof Stress, psi, shown in Column Header Below | |||||||

| 120 000 | 130 000 | 135 000 | 150 000 | 175 000 | |||

| ¼ | 28 | 0.0364 | 4050 | 4375 | 4550 | 5050 | 5900 |

| ¼ | 20 | 0.0318 | 3525 | 3825 | 3975 | 4400 | 5150 |

| ⁵⁄₁₆ | 24 | 0.0580 | 6300 | 6825 | 7100 | 7875 | 9200 |

| ⁵⁄₁₆ | 18 | 0.0524 | 5700 | 6175 | 6400 | 7125 | 8300 |

| ⅜ | 24 | 0.0878 | 9350 | 10 125 | 10 525 | 11700 | 13625 |

| ⅜ | 16 | 0.0775 | 8250 | 8950 | 9300 | 10 300 | 12 050 |

| 7⁄16 | 20 | 0.1187 | 12 350 | 13 400 | 13 900 | 15 450 | 18 050 |

| 7⁄16 | 14 | 0.1063 | 11 100 | 12 000 | 12 450 | 13 850 | 16 150 |

| 1⁄2 | 20 | 0.1599 | 16 300 | 17 650 | 18 350 | 20 400 | 23 800 |

| 1⁄2 | 13 | 0.1419 | 14 500 | 15 700 | 16 300 | 18 100 | 21 100 |

| 9⁄16 | 18 | 0.203 | 20 200 | 21 900 | 22 800 | 25 300 | 29 500 |

| 9⁄16 | 12 | 0.182 | 18 200 | 19 700 | 20 400 | 22 700 | 26 500 |

| 5⁄8 | 18 | 0.256 | 25 000 | 27 000 | 2 100 | 31 200 | 36 400 |

| 5⁄8 | 11 | 0.226 | 22 000 | 23 900 | 24 800 | 27 500 | 32 100 |

| 3⁄4 | 16 | 0.373 | 34 700 | 37 600 | 39 000 | 43 400 | 50 600 |

| 3⁄4 | 10 | 0.334 | 31 000 | 33 600 | 35 000 | 38 800 | 45 200 |

| 7⁄8 | 14 | 0.509 | 45 000 | 48 800 | 50 600 | 56 400 | 65 600 |

| 7⁄8 | 9 | 0.462 | 40 800 | 44 200 | 46 000 | 51 200 | 59 600 |

| 1 | 12 | 0.663 | 55 600 | 60 400 | 62 600 | 69 600 | 81 200 |

| 1 | 8 | 0.606 | 51 000 | 55 200 | 57 200 | 63 600 | 74 200 |

| 1 1⁄8 | 12 | 0.856 | 68 000 | 73 800 | 76 600 | 85 000 | 99 200 |

| 1 1⁄8 | 8 | 0.790 | 62 800 | 68 000 | 70 600 | 78 600 | 91 600 |

| 1 1⁄8 | 7 | 0.763 | 60 750 | 68 750 | 68 250 | 75 750 | 88 500 |

| 1 1⁄4 | 12 | 1.073 | 80 500 | 87 250 | 90 500 | 100 500 | 117 250 |

| 1 1⁄4 | 8 | 1.000 | 75 000 | 81 250 | 84 250 | 93 750 | 109 250 |

| 1 1⁄4 | 7 | 0.969 | 72 750 | 78 750 | 81 750 | 90 750 | 106 000 |

| 1 3⁄8 | 12 | 1.315 | 92 750 | 100 500 | 104 250 | 116 000 | 135 250 |

| 1 3⁄8 | 8 | 1.233 | 87 000 | 94 250 | 98 000 | 108 750 | 126 750 |

| 1 3⁄8 | 6 | 1.155 | 81 500 | 88 250 | 91 500 | 101 750 | 118 750 |

| 1 1⁄2 | 12 | 1.581 | 104 250 | 113 000 | 117 500 | 130 500 | 152 250 |

| 1 1⁄2 | 8 | 1.492 | 98 500 | 106 750 | 110 750 | 123 000 | 143 500 |

| 1 1⁄2 | 6 | 1.492 | 92 750 | 100 500 | 104 250 | 116 000 | 135 250 |

ABased upon the following equation (this equation should not be used for extrapolating values beyond the size ranges listed in this table) and rounded to nearest 1⁄2 ksi equivalent:

CPL = (1 - 0.30 D) x f x As

where:

CPL = cone stripping proof load, lbf.,

D = nominal diameter of nut, in.,

f = minimum proof stress of nut, psi.,

As = tensile stress area of nut, in.2 = 0.7854 [D - 0.9743 ⁄ n]2, and

n = threads per inch.

Mechanical Properties

Method of Mechanical Tests—All tests shall be conducted in accordance with Test Methods and Definitions A370. unless otherwise specified.

For the purpose of determining conformance to the product specification requirements, specimens shall be obtained from the production material, or, in the case of forgings, from separately forged test blanks prepared from the stock used to make the finished product. Heat treatment shall be completed prior to removal of material for mechanical testing.

If separately forged test blanks are used, they shall be of the same heat of steel, be subjected to substantially the same reduction and working as the production forging they represent, be heat treated in the same furnace charge and under the same conditions as the production forging, and be of the same nominal thickness as the maximum heat treated thickness of the production forging.

Bars—Tension and impact tests representing bar stock shall be taken in accordance with the requirements of Annex A1 of Test Methods and Definitions A370. Impact tests are not required on bars 1⁄2 in. and under in diameter.

Components, Machined from Heat Treated Bar— Mechanical properties of bolting components machined from heat treated bar shall be represented by the tests conducted on the bar in accordance with 8.4.

Components, All Classes—Produced by other methods—When bolting components have been produced by forming, when they have been subjected to heat treatment, or when the nominal thread size falls into a different diameter range than that of the starting bar as shown in the applicable specifications, then tests shall be conducted on material taken from those components.

Tension test specimens taken from finished components shall be machined to the form and dimensions and from the positions shown in Annex A3 of Test Methods and Definitions A370. Impact tests are not required on material from externally threaded components when the thread diameter is 1⁄2 in. and under.

Hardness Requirements

The material shall conform to the hardness requirements prescribed in the product specification. Hardness testing shall be performed in accordance with Test Methods and Definitions A370.

Tensile tests prevail over hardness tests in the event a conflict exists relative to minimum strength unless otherwise specified in the product specification.

Tensile Requirements

Bars and Specimens Machined From Components — The bolting component material shall conform to the tensile property requirements prescribed in the product specification.

Proof Load and Cone Proof Requirements

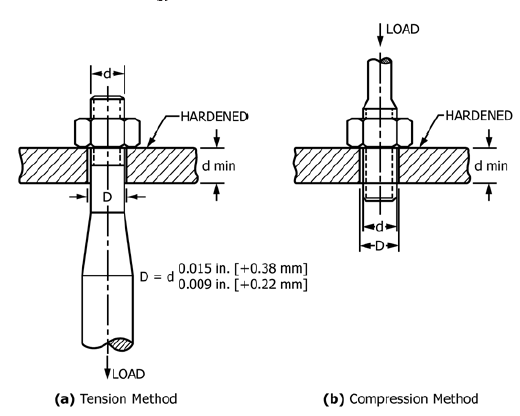

Proof Load Test—Nuts shall be assembled on a threaded mandrel or a test bolt as illustrated in Fig. 1(a) Tension Method or (b) Compression Method. The minimum proof load required by the product specification shall be applied using a free running cross head speed of 1.0 in. [25 mm] per minute maximum and shall be held for at least 10 s. The nut shall resist this load without stripping or rupture, and shall be removable by hand, without use of tooling, after the load is released. A wrench may be used to loosen the nut one-half turn maximum to start it in motion. The test shall be discarded if the threads of the mandrel or test bolt are damaged during the test.

Proof Load Tetsing -- Nuts

Cone Proof Load Test—This test is performed when visible surface discontinuities become a matter of issue. The test uses a conical washer and threaded mandrel to determine the load-carrying ability of hardened steel nuts through 11⁄2 in. [36 mm] in diameter assembled as shown in Fig. 2. The minimum cone proof load required by the product specification shall be applied using a free running cross head speed of 0.12 in. [3 mm] per minute maximum and shall be held for at least 10 s. The nut shall support its specified cone proof load without stripping or rupture.

Cone-Proof Test

Impact Requirements

The material shall conform to the impact requirements prescribed in the product specification.

Sampling for impact testing shall conform to the product specification.

The impact test specimen shall have the form and dimensions shown in Fig. 10 of Test Methods and Definitions A370. for the Charpy V-notch specimen, Type A. The longitudinal axis of the specimen shall be parallel to the direction of rolling or, in the case of forgings, to the longest axis of the component the test bar represents. The notch shall be located on the test specimen surface which most closely approaches a radial direction. The base of the notch shall be as nearly as practicable perpendicular to the longest axis of the component.

Workmanship, Finish, and Appearance

The bolting components shall conform to the dimensions, tolerances and finish as specified in the purchase order or in the individual product specification.

Bars—Bars shall meet the dimensional requirements of Specifications A29/A29M or A484/A484M as applicable.

Bolts, Screws, Studs, and Stud Bolts—Points shall be flat and chamfered or rounded at the option of the manufacturer. The length of the point on studs and stud bolts shall be not less than one nor more than two complete threads as measured from the extreme end parallel to the axis. Length of studs and stud bolts shall be measured from first thread to first thread. Bolts, studs, and bolting material shall be capable of passing inspection in accordance with Specification F788/ F788M.

Hex Bolts—Unless otherwise specified in the purchase order heads shall be in accordance with the dimensions of ASME B18.2.1 or B18.2.3.6M and the Heavy Hex screw series, should be used, except the maximum body diameter and radius of fillets may be the same as for the heavy hex bolt series. The body diameter and head fillet radius for sizes of heavy hex cap screws and bolts that are not shown in their respective tables in the ASME specifications may be that shown in the corresponding hex cap screw and bolt tables respectively. Unless otherwise specified on the purchase order Metric Heavy Hex Screws shall be in accordance with ASME B18.2.3.3M.

Socket Heads—Unless otherwise specified socket head screws shall be in accordance with ASME B18.3 or ISO 4762.

Studs and Stud Bolts—Unless otherwise specified in the purchase order, dimensions and tolerances for studs and stud bolts shall be in accordance with ASME B18.31.2.

External Threads—Threads shall either be formed after heat treatment or heat treatment shall be performed in atmosphere control furnaces.

Thread Form—Unless otherwise specified external threads shall be in accordance with ASME B1.1, Class 2A fit, or ASME B1.13M, Class 6g fit.

Inch Series—Sizes 1 in. and smaller in diameter shall be coarse thread series, and those 11⁄8 in. and larger in diameter shall be eight pitch thread series, unless otherwise specified.

Nuts—Unless otherwise specified nuts shall be hexagonal in shape and the American National Standard Heavy Hex Series shall be used. In addition nuts shall either be double chamfered or have a machined or forged washer face, at the option of the manufacturer, and shall conform to the angularity requirements of the applicable ASME specification. See ASME B18.2.2, B18.2.6, B18.2.4.6M, and B18.2.6M. Nuts shall be capable of passing inspection in accordance with Specification F812.

Thread—Unless otherwise specified threads in nuts shall be in accordance with ASME B1.1 Class 2B fit or B1.13M Class 6H fit, and shall be gauged in accordance with ASME B1.2 or B1.3M

Inch Series—Unless otherwise specified, nuts up to and including 1 in. in diameter shall be UNC Series Class 2B fit and nuts over 1 in. nominal size shall be 8 UN Series Class 2B fit.

If a scale-free bright finish is required, this finish shall be specified in the purchase order.

Decarburization

Depth—The depth of decarburization (total + partial) shall be determined after completion of all heat treatment and shall not exceed the limits shown in Test Method F2328 Class 3, regardless of grade being tested.

Test Method—Decarburization test shall be performed in accordance with Test Method F2328 or F2328M as applicable.

Decarburization test only applies to carbon and alloy steel bolting components.

Number of Tests

Chemical Analysis—One test per heat.

Tension Tests, and, When Applicable, Impact Tests, Bar, Rod, or Wire or Components, or Both, Machined

from Heat Treated Bar, Rod, or Wire—Batch processing: One test per lot as defined in 3.1.9.1.

Continuous processing as defined in 3.1.9.2: Not fewer than two tension and, when applicable, impact

tests are required for each lot containing 20 000 lb [9000 kg] or less. Every additional 10 000 lb

[4500 kg] or fraction thereof requires one additional test.

Tension Tests, Components Produced as Defined in 8.6—The number of machined specimens or full size bolting

| Lot Size (pc) | Sample Size |

|---|---|

| 50 and less | 2 |

| 51 to 500 | 3 |

| 501 to 35 000 | 5 |

| Over 35 000 | 8 |

Decarburization Test, Carbon and Alloy Steel, Components Produced as Defined in 8.6 and Studs Machined from Cold or Hot Rolled and Heat Treated Bar Whose Diameter Prior to Machining Threads is Within 0.06 in. [1.5 mm] in Diameter of the Maximum Thread Diameter—One test per lot (see 3.1.9).

Hardness Tests:

Retests And Rework

If the results of any tension test do not conform to the requirements specified in the product specification, retests are permitted as outlined in Test Methods and Definitions A370. If the results of a tension test are less than specified because a flaw becomes evident in the test specimen during testing, a retest shall be allowed provided that the flaw is not attributable to ruptures, cracks, or flakes in the steel. Retesting shall be performed on twice the number of samples originally specified.

When the impact test acceptance requirements of the specification are not met, one retest of three additional specimens from the same test location may be performed. Each individual test value of the retested specimens shall be equal to or greater than the specified minimum average value.

Repair by welding is prohibited.

Inspection

The supplier shall afford the purchaser or inspector representing the purchaser all reasonable facilities necessary to satisfy him that the material is being produced and furnished in accordance with this specification and the applicable product specification. Site inspection required by the purchaser shall not interfere unnecessarily with the supplier’s operations.

Personnel performing the nondestructive examination shall be qualified and certified in accordance with a written procedure conforming to ASNT Recommended Practice No. SNT-TC-1A (1988 or later) or another national standard that is acceptable to both the purchaser and the supplier.

Rejection And Rehearing

Samples representing material rejected by the purchaser shall be preserved until disposition of the claim has been agreed to between the supplier and the purchaser.

Certification

Certification shall include a statement that the material or parts, or both, were manufactured, sampled, tested, and inspected in accordance with the requirements of the individual product specification, including the specification number, year date of issue, grade symbol, and manufacturer’s identification symbol. In addition, the certification shall include the results of all tests required by this specification, the product specification, and the purchase order. The supplier shall provide additional specific information as required by the product specification or purchase order.

A certificate printed from or used in electronic form from an electronic data interchange (EDI) transmission shall be regarded as having the same validity as a counterpart printed in the certifier’s facility. The content of the EDI transmitted document shall also conform to any existing EDI agreement between the purchaser and the supplier.

Notwithstanding the absence of a signature, the organization submitting either the EDI transmission or paper copies of certificates of test is responsible for the content of the report.

Product Marking

Bars shall be marked in accordance with Specifications A29/A29M or A484/A484M as applicable. Bolting materials, including threaded bar, furnished bundled and tagged, shall carry the grade symbol for the material and the manufacturer’s identification symbol or name. Marking of individual bars is not required as long as the bars are bundled and tagged or boxed.

Bar coding is acceptable as a supplementary identification method. Coding should be consistent with AIAG B-5 02.00. If used on small items, the bar coding may be applied to the box or a substantially applied tag.

Grade and manufacturer’s identification symbols shall be applied to one end of studs 3⁄8 in. [10 mm] in diameter and larger and to the heads of bolts and screws 1⁄4 in. [6 mm] in diameter and larger. If the available area is inadequate, the grade symbol may be marked on one end and the manufacturer’s identification symbol marked on the other end of studs. Bolts and screws shall preferably be marked on top of the head. When necessary, bolts and screws may be marked on the side of the head provided the marking does not interfere with wrenchability or become damaged during tightening to the extent that legibility is lost. Products shall not be marked on the bearing surface or be marked in a way that alters the dimensions or geometric characteristics of the bearing surface.

Grade and manufacturer’s identification symbols shall be applied to all nuts regardless of size.

Hollow forgings shall be marked with the heat number or heat symbol and grade.

When product is altered in a manner which changes specified requirements, it is the responsibility of the current certifying organization to ensure that the product marking is appropriately revised. This includes the removal of the name or symbol of the previous certifying organization.

For purposes of product marking and test reports, the manufacturer is considered the organization that certifies the fastener was manufactured, sampled, tested, and inspected in accordance with the specification and the results have been determined to meet the requirements of the specification.

Dual Marking—Product that meets all requirements of more than one grade within or between product specifications may be marked with both grade markings. The dual marking shall consist of the complete marking requirement for each grade, as required by the product specification, separated by a slash. For example, for Grade A193 B7 and A320 L7, the dual marking would be B7/L7.

Packaging, Package Marking and Loading for Shipment

Packaging, marking, and loading for shipment shall be in accordance with Practices A700.

Keywords

austenitic stainless steel; bolts, steel; bolting components, steel; bolting materials; components, steel; nickel alloy bolting; nuts, steel; pressure vessel service; screws; stainless steel bolting; steel bars, alloy; steel bars, carbon; steel bars, stainless; steel bolting; studs; temperature service applications, high; temperature service applications, low; turbine materials; washers.

Supplementary Requirements

One or more of the following supplementary requirements shall be applied only when specified by the purchaser in the purchase order or contract. The specified supplementary requirements shall be completed prior to shipment of the product.

Product MarkingGrade and manufacturer’s identification symbols shall be applied to one end of studs and to the heads of bolts of all sizes. If the available area is inadequate, the grade symbol may be marked on one end and the manufacturer’s identification symbol marked on the other end.

Stress RelievingA stress relieving operation shall follow straightening after heat treatment. The minimum stress relieving temperature shall be 100 °F [55 °C] below the tempering temperature. Tests for mechanical properties shall be performed after stress relieving.

Heat AnalysisAn analysis of each remelt ingot shall be made by the steel manufacturer to determine the percentages of those elements specified in the individual product specification. The chemical analysis thus determined shall conform to the requirements of the individual product specification.

Sequential or Continuous Strand CastingWhen multiple heats of the same chemical composition range are sequentially strand cast, the heats shall be separated by an established procedure such that intermix material shall not be supplied.

Bolting for Dynamic ServiceBolting for dynamic service shall be examined for surface discontinuities and decarburization.

Surface Discontinuities:

Decarburization:

The wet fluorescent magnetic particle examination method shall be applied to 100 % of the lot in accordance with Practice E1444. Acceptance criteria shall be in accordance with S57.

Liquid Penetrant ExaminationThe fluorescent liquid penetrant examination method shall be applied to 100 % of the lot in accordance with Practice E1417. Acceptance criteria shall be in accordance with S57.

Acceptance CriteriaOnly indications, which have a dimension greater than 1⁄16 in., shall be considered relevant. A linear indication is one having a length greater than three times the width. A rounded indication is one of circular or elliptical shape with a length equal to or less than three times the width. All surfaces examined shall be free of the following:

Bolting shall receive Positive Material Identification to ensure that the purchaser is receiving bolting of the correct material grade prior to shipment of the bolting. This examination is a method to assure that no material grade mix-up has happened during manufacturing and marking of bolting.

Bolting shall receive a Positive Material Identification examination by Guide E1916.

The quantity examined shall be 100 % of the bolting.

All bolting that are not of the correct material grade shall be rejected.

The method of bolting marking after examination shall be agreed upon between the manufacturer and purchaser.

Pressure Equipment Directive—Mechanical TestingCharpy impact testing shall be done at the lowest scheduled operating temperature, but not higher than 20 °C [68 °F].

The frequency of impact testing shall be the same as that specified in the product specification for the tension test, with three individual Charpy test specimens for each required tension test.

The minimum individual energy for the Charpy impact test shall be 20 ft-lb [27 J].

The minimum elongation in the tension test shall be measured on a gauge length of five times the diameter of the test specimen, and shall not be less than 14 %.

Impact and tension test results shall be included in the product certification.

Heat Treat ChartsThe supplier shall provide heat treat charts as a part of the order documentation.

Hardness TestingEach piece of bolting shall be hardness tested and found to meet the requirements of the product specification or this standard, as applicable. A minimum sample consisting of 10 % of the pieces in each lot shall be tested using an indentation method in accordance with Test Methods and Definitions A370.. Each piece in the sample shall meet the hardness requirements. The balance of the lot may be tested using either the indentation method per Test Methods and Definitions A370. or electromagnetic sorting in accordance with Practice E566. If any piece in the sample is outside of the specified hardness requirements, then the lot shall be rejected and either reprocessed and resampled, or tested 100 % by indentation hardness methods.

Ultrasonic Examination of Bolting in Sizes Greater than 2 in. [50 mm] in Cross SectionAll bolting with a major cross section greater than 2 in. [50 mm] shall be subjected to ultrasonic inspection (UT) prior to threading.

Ultrasonic inspection shall be carried out using L-wave transducers in the radial direction.

Search units shall not exceed 1 in.2 [645 mm2] in area and shall have a nominal frequency of 2 or 21⁄4 MHz.

Inspection sensitivity shall be established using a first back reflection set at 80 % of full screen height (FSH).

Indications whose amplitude exceeds 20 % FSH and those which cause the back reflection signal amplitude to decrease to 40 % or less FSH are not acceptable.

Phosphorus and Sulfur MaximumsThe phosphorus and sulfur content of carbon and low alloy steels shall be 0.025 % max.

Product InspectionSampling for dimensional, thread fit and visual inspection of product shall be performed in accordance with ASME B18.18 Category 2 / ASME B18.18 Category 3.

Marking for Lot TraceabilityIn addition to the requirements stated in Section 20, bolting components (purchaser to designate whether bolts or nuts or other specific items apply) shall be individually hard marked with a traceability code that provides full traceability to the lot, with a lot as defined in 3.1.9 for fasteners. The traceability code shall be defined by the bolting manufacturer and shall be reported on the certification.

Eddy Current InspectionEddy current examination shall be applied to 100 % of the lot in accordance with a defined practice approved by the purchaser. Reject levels for linear indications shall be based on the alarm response from a surface notch with a maximum depth of 0.012 in. [0.030 mm] in a calibration bar.

Ultrasonic InspectionUltrasonic examination shall be applied to 100 % of the lot in accordance with a defined practice approved by the purchaser. Reject levels for linear indications shall be based on the alarm response from a surface notch with a maximum depth of 0.012 in. [0.030 mm] in a calibration bar.

Sampling For Hardness TestingFinished components or blanks from each heat treatment charge shall be subjected to hardness testing. The number of samples tested shall meet the requirements of Guide F1470 , Table 3, Sample Size B.

Maximum Hardness for Carbon and Alloy SteelThe maximum hardness of components shall not exceed 32 HRC [302 HBW].

Passivation of Stainless Steel BoltingStainless Steel Bolting components shall be passivated in accordance with Practice A380 or Specification A967 at the option of the manufacturer or shall be electropolished.

Referenced Documents

The following documents shall form a part of this specification to the extent specified. The latest issue shall apply unless otherwise specified.

ASTM Standards:

A29/A29M Specification for General Requirements for Steel

Bars, Carbon and Alloy, Hot-Wrought.

A193/A193M Specification for Alloy-Steel and Stainless

Steel Bolting for High Temperature or High Pressure Service and Other Special Purpose

Applications.

A194/A194M Specification for Carbon Steel, Alloy Steel,

and Stainless Steel Nuts for Bolts for High Pressure or High Temperature Service, or Both

A320/A320M Specification for Alloy-Steel and Stainless

Steel Bolting for Low-Temperature Service.

A370. Test Methods and Definitions for Mechanical Testing

of Steel Products.

A380 Practice for Cleaning, Descaling, and Passivation of

Stainless Steel Parts, Equipment, and Systems.

A437/A437M Specification for Stainless and Alloy-Steel

Turbine-Type Bolting Specially Heat Treated for High-Temperature Service.

A453/A453M Specification for High-Temperature Bolting,

with Expansion

Coefficients Comparable to Austenitic Stainless Steels.

A484/A484M Specification for General Requirements for

Stainless Steel Bars, Billets, and Forgings.

A540/A540M Specification for Alloy-Steel Bolting for

Special

Applications.

A700 Guide for Packaging, Marking, and Loading Methods

for Steel Products for Shipment.

A751 Test Methods, Practices, and Terminology for Chemical

Analysis of Steel Products.

A788/A788M Specification for Steel Forgings, General

Requirements.

A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and

Ferroalloys.

A967 Specification for Chemical Passivation Treatments for Stainless Steel

Parts.

A1014/A1014M Specification for Precipitation-Hardening

Bolting (UNS N07718) for High Temperature Service.

E3 Guide for Preparation of Metallographic Specimens

E384 Test Method for Microindentation Hardness of Materials

E566 Practice for Electromagnetic (Eddy Current) Sorting of Ferrous Metals

E1417 Practice for Liquid Penetrant Testing

E1444 Practice for Magnetic Particle Testing

E1916 Guide for Identification of Mixed Lots of Metals

F788/F788M Specification for Surface Discontinuities of Bolts, Screws, and Studs,

Inch and Metric Series.

F812 Specification for Surface Discontinuities of Nuts, Inch and Metric Series

F1470 Practice for Fastener Sampling for Specified

Mechanical Properties

and Performance Inspection

F2328 Test Method for Determining Decarburization and Carburization in Hardened and

Tempered Threaded Steel Bolts, Screws, Studs, and Nuts

F2328M Test Method for Determining Decarburization and Carburization in Hardened and

Tempered Threaded Steel Bolts, Screws, Studs, and Nuts (Metric)

AIAG Standard:

AIAG B-5 02.00 Primary Metals Identification Tag Application Standard

ASME Standards:

B1.1 Screw Threads

B1.13M Metric Screw Threads – M Profile

B1.2 Gages and Gaging for Unified Screw Threads

B1.3M Screw Thread Gaging Systems for Dimensional Acceptability of Metric Screw

Threads

B18.2.1 Square and Hex Bolts and

Screws

B18.2.2 Metric Heavy Hex Nuts

B18.2.3.3M Metric Heavy Hex

Screws

B18.2.3.6M Metric Heavy Bolts

B18.2.4.6M Nuts for General

Applications

B18.2.6 Fasteners Used in Structural

Applications

B18.2.6M Metric Fasteners for Use in

Structural Applications

B18.3 Hexagon Socket and Spline Socket

Screws

B18.18 Quality Assurance for Fasteners

B18.31.2 Continuous Thread Stud,

Double-End Stud, and Flange Bolting Stud (Stud Bolt) (Inch Series)

ISO Standards:

ISO 4762 Hex Socket Cap Screw

Other Documents:

ASNT Recommended Practice No. SNT-TC-1A